2025 Top Ball Valve Innovations: Essential Types and Features You Need to Know

In recent years, the ball valve industry has witnessed a remarkable evolution, driven by advancements in technology and the ever-growing demand for efficient flow control solutions. According to a market research report by Grand View Research, the global ball valve market size was valued at approximately $8.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth underscores the critical role that ball valves play in various sectors, including oil and gas, water and wastewater management, and chemical processing.

Industry expert Dr. Sarah Patel, a prominent authority on fluid control systems, emphasizes the significance of innovation in this field. She states, "The future of ball valves lies in the integration of smart technology that enhances operational efficiency and reliability." This sentiment captures the essential types and features that will define ball valve innovations in 2025. As we delve into this topic, understanding the emerging trends and the technological advancements that are reshaping the ball valve landscape will be vital for professionals seeking to maintain a competitive advantage in their industries.

Advancements in Ball Valve Technology for Enhanced Performance in 2025

The ball valve technology is witnessing remarkable advancements in 2025, aimed at enhancing performance across various applications. One of the standout innovations is the integration of smart technology, allowing for real-time monitoring and control. This feature not only provides operators with immediate data on valve performance but also enables predictive maintenance, reducing downtime and enhancing operational efficiency. The incorporation of IoT devices ensures seamless communication within automation systems, making ball valves smarter than ever.

Additionally, materials science plays a critical role in the evolution of ball valves. The development of new, lightweight composite materials offers increased durability and corrosion resistance, significantly extending the lifespan of these valves in harsh environments. Furthermore, advanced sealing technologies have been introduced, minimizing leakage risks and improving safety standards. This combination of smart technology and innovative materials positions modern ball valves as indispensable components in industries ranging from oil and gas to water management, ensuring they can meet the increasingly stringent demands of today’s market.

2025 Top Ball Valve Innovations: Essential Types and Features You Need to Know

| Type | Material | Size Range (inches) | Pressure Rating (PSI) | Key Features |

|---|---|---|---|---|

| Full Port Ball Valve | Stainless Steel | 1 - 12 | 1500 | Enhanced flow capacity, minimal pressure drop |

| Trunnion Mounted Ball Valve | Carbon Steel | 2 - 30 | 3000 | Suitable for high pressure, better sealing |

| Floating Ball Valve | Brass | 1/2 - 6 | 600 | Simple design, cost-effective, easy to maintain |

| Electric Ball Valve | PVC | 1 - 10 | 150 | Automated operation, precise control, energy efficient |

| Cryogenic Ball Valve | Stainless Steel | 2 - 8 | 2500 | Designed for low-temperature applications, reliable performance |

Key Features of the Top Ball Valve Types Revolutionizing Fluid Control

In 2025, the landscape of ball valve technology is poised for significant advancements, with several essential types emerging as game-changers in fluid control. One of the key innovations is the introduction of smart ball valves, which integrate IoT technology for real-time monitoring and automated adjustments. These valves can communicate data regarding flow rates, pressure levels, and overall system health, allowing for more efficient management and troubleshooting in various industrial applications.

Another vital feature in modern ball valves is the enhanced sealing mechanisms. New materials and design innovations, such as self-adjusting seals and anti-static features, significantly improve their durability and reliability. These advancements not only extend the life of the valves but also reduce the risk of leakage, ensuring a safer operational environment. Coupled with increased resistance to corrosion and extreme temperatures, these features make modern ball valves indispensable in critical sectors such as oil and gas, water treatment, and chemical processing.

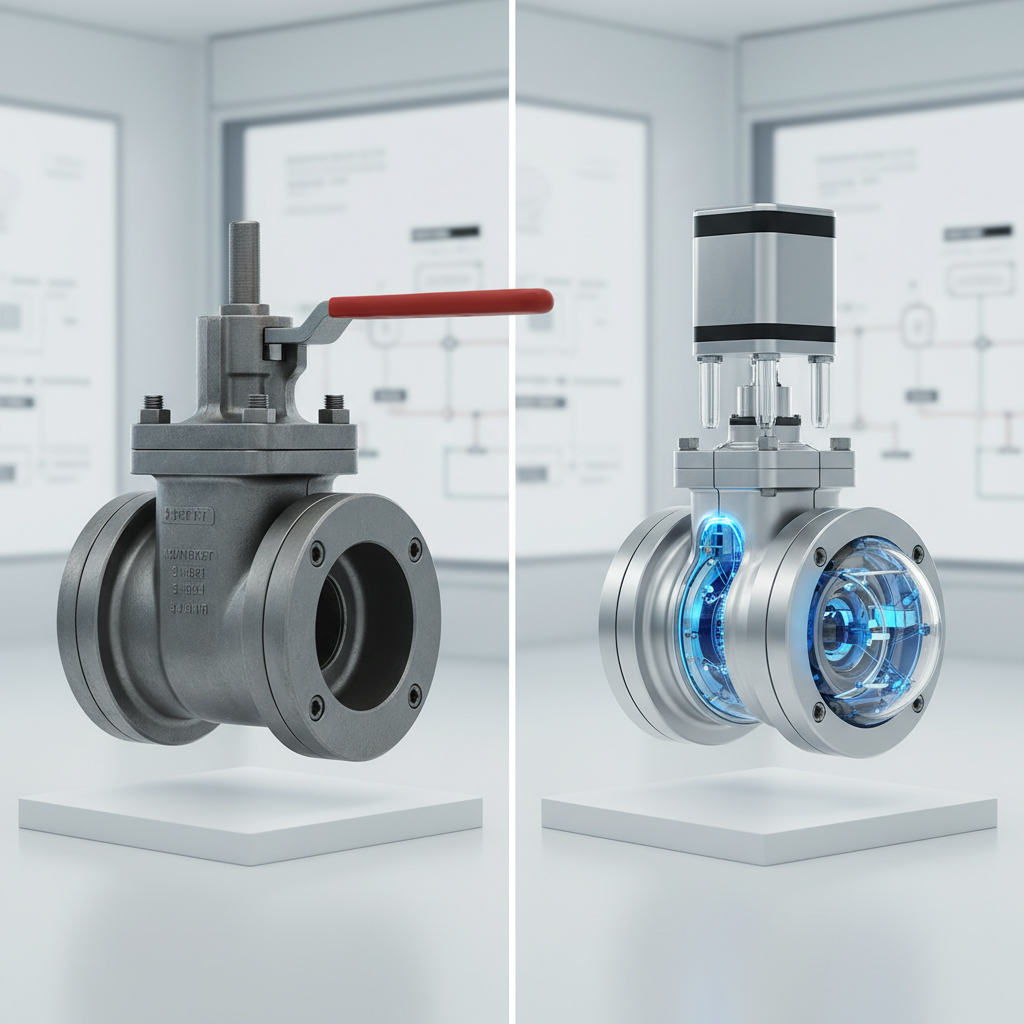

Comparative Analysis of Traditional vs. Innovative Ball Valve Designs

When comparing traditional and innovative ball valve designs, it's essential to recognize the advancements that modern technologies have brought to the industry. Traditional ball valves are typically made of a solid, robust material, ensuring durability and reliability. However, they often lag in terms of efficiency and adaptability, making them less suitable for dynamic environments where conditions frequently change. Innovative designs now incorporate advanced materials and smart technologies, allowing for enhanced performance, reduced weight, and improved leakage prevention, making them more effective for a variety of applications.

Tip: When selecting a ball valve for your project, consider the specific operational conditions it will face. Look for features like automated controls or integrated sensors that can enhance performance and provide real-time monitoring capabilities.

Moreover, the latest innovations emphasize sustainability and energy efficiency. Many new designs focus on reduced friction and improved flow characteristics, which can lead to significant energy savings over the lifespan of the valve. These innovations are not only better for the environment, but they also contribute to lower operational costs for businesses.

Tip: Always review the materials and technologies used in new ball valve designs. Choosing valves made from eco-friendly materials can enhance your project's overall sustainability and align with corporate social responsibility goals.

Eco-Friendly Ball Valve Solutions: Sustainability Trends for 2025

As we approach 2025, the shift towards eco-friendly ball valve solutions is becoming more prominent in various industries. Manufacturers are increasingly focusing on creating valves that not only perform efficiently but also contribute to sustainability goals. This trend is driven by regulatory pressures and a growing recognition of the importance of reducing carbon footprints. Innovations such as biodegradable materials and energy-efficient manufacturing processes are leading the charge in the development of green ball valves, ensuring that environmental considerations are integral to their design.

In addition to material advancements, smart technologies are enhancing the sustainability aspect of ball valves. The integration of IoT connectivity allows for real-time monitoring of valve performance and energy usage, helping companies optimize their operations and reduce waste. Moreover, these smart valves can predict maintenance needs, further extending their lifespan and efficiency. As industries adapt to more sustainable practices, the implementation of eco-friendly ball valve solutions will not only meet legislative requirements but also promote a culture of responsibility towards the environment.

Future Trends in Smart Ball Valves: Automation and Integration in Industry

The future of ball valves is increasingly intertwined with automation and smart technology, reflecting a broader trend across the industrial sector. Smart ball valves are being designed to integrate seamlessly with sophisticated control systems, enabling real-time monitoring and sharper control over fluid dynamics. This shift not only enhances operational efficiency but also reduces maintenance costs by providing predictive analytics that help prevent issues before they arise.

Tips: When selecting smart ball valves, consider the compatibility of sensors and communication protocols with your existing infrastructure. Investing in valves that offer robust data analytics capabilities can also provide valuable insights into system performance, helping to optimize operations.

Additionally, as industries strive for sustainable practices, smart ball valves offer features that contribute to energy efficiency and reduced emissions. The integration of IoT (Internet of Things) technologies allows for automated adjustments based on real-time data, ensuring that systems operate at optimal levels while minimizing waste. This evolution signals a significant step towards more intelligent and environmentally friendly industrial processes.

Tips: Look for smart ball valves equipped with energy-saving features and customizable settings to tailor operations to specific needs. Regularly updating software and maintaining equipment can also enhance performance and longevity.

Related Posts

-

The Future of Innovation in Ball Valve Technology

-

How to Choose the Right Ball Valve for Your Industrial Needs

-

How to Choose the Right Ball Valve for Your Industrial Applications

-

Why Choosing the Right Ball Valve Can Enhance Your Industrial Efficiency and Reduce Costs

-

Understanding the Unique Features of Ball Valve Types for Industrial Applications

-

How to Choose the Right Ball Valve for Your Industrial Needs