Best Ppsu Pex Fittings Guide for Reliable Plumbing Solutions

When it comes to ensuring a reliable plumbing system, the choice of materials and fittings plays a crucial role. Among the various options available, Ppsu Pex Fittings have gained significant attention due to their exceptional durability and performance. Made from high-quality polyphenylsulfone (PPSU), these fittings are designed to withstand high temperatures and resist chemical corrosion, making them an ideal choice for both residential and commercial plumbing applications.

In this comprehensive guide, we will explore the advantages of Ppsu Pex Fittings and how they can provide long-lasting solutions for your plumbing needs. We will delve into the characteristics that set them apart from traditional fittings, addressing concerns such as installation ease, flexibility, and overall efficiency. Whether you are a seasoned plumber or a DIY enthusiast, understanding the nuances of Ppsu Pex Fittings will empower you to make informed decisions that enhance the reliability of your plumbing systems.

Join us as we navigate through the best practices and recommendations for selecting and using Ppsu Pex Fittings, ensuring that your plumbing solutions are not only effective but also sustainable over time. Together, we can find the fitting solutions that promise durability and peace of mind for years to come.

Overview of PPSU and PEX Materials in Plumbing Applications

PPSU (Polyphenylsulfone) and PEX (Cross-Linked Polyethylene) have emerged as top materials in the plumbing industry, thanks to their enhanced performance and reliability. PPSU is known for its high-temperature resistance and strength, making it an ideal choice for applications that require durability under extreme conditions. According to a report by the American Society for Testing and Materials (ASTM), PPSU fittings can withstand temperatures exceeding 180°C, ensuring long-term performance in both hot and cold water systems. PEX, on the other hand, is celebrated for its flexibility and easy installation. The versatility of PEX allows for simpler routing through walls and ceilings, reducing the number of joints and potential leak points.

When considering plumbing solutions with these materials, it's essential to understand their properties. For example, both PPSU and PEX are resistant to corrosion and scale buildup, with studies indicating that PEX can reduce energy loss due to its insulating properties, leading to better energy efficiency in plumbing systems. However, it’s vital to adhere to local plumbing codes during installation to ensure compliance and safety.

Tips: When selecting fittings for your plumbing project, ensure they are compatible with the materials you have chosen. Additionally, consider the temperature and pressure ratings generally provided by industry reports to select fittings that will provide long-lasting performance—this is key to preventing future plumbing issues. Lastly, investing in quality fitting materials can save you time and money by minimizing the need for repairs and replacements down the line.

Key Benefits of Using PPSU PEX Fittings in Modern Plumbing Systems

PPSU PEX fittings have gained immense popularity in modern plumbing systems due to their unique combination of durability, flexibility, and resistance to extreme temperatures. One of the key benefits of using these fittings is their high resistance to chemical corrosion, making them ideal for both residential and commercial applications. Unlike traditional fittings, PPSU PEX fittings can withstand various harsh substances, ensuring long-lasting performance and reducing the risk of leaks and failures over time.

Another significant advantage of PPSU PEX fittings is their lightweight and easy installation, which can significantly reduce labor costs and time during plumbing projects. These fittings can be easily manipulated and adapted to fit into tight spaces, providing an efficient solution for complex plumbing layouts. Moreover, their excellent thermal properties help maintain the temperature of the water, promoting energy efficiency and comfort in plumbing systems, particularly in areas where hot or cold water needs to be consistently supplied.

Industry Standards and Certifications for Reliable PPSU PEX Fittings

When selecting PPSU PEX fittings for plumbing solutions, understanding industry standards and certifications is crucial for ensuring reliability and safety. PPSU (Polyphenylsulfone) is recognized for its exceptional thermal stability, chemical resistance, and durability, making it an ideal choice for high-performance plumbing systems. According to the ASTM F876 standard, PEX tubing and fittings must exhibit high resistance to impact and oxidative deterioration, which is essential in various plumbing applications, from residential to industrial.

Certifications play a significant role in assessing the quality of PPSU PEX fittings. The National Sanitation Foundation (NSF) certifies products that meet public health and safety standards, which is vital for potable water applications. Furthermore, the International Association of Plumbing and Mechanical Officials (IAPMO) provides another layer of assurance through its product certification programs, ensuring that PPSU PEX fittings comply with strict performance specifications. According to recent market research from Technical Insights, products that comply with these certifications tend to perform better and last longer in real-world applications, ensuring a lower risk of leaks and maintenance issues over time.

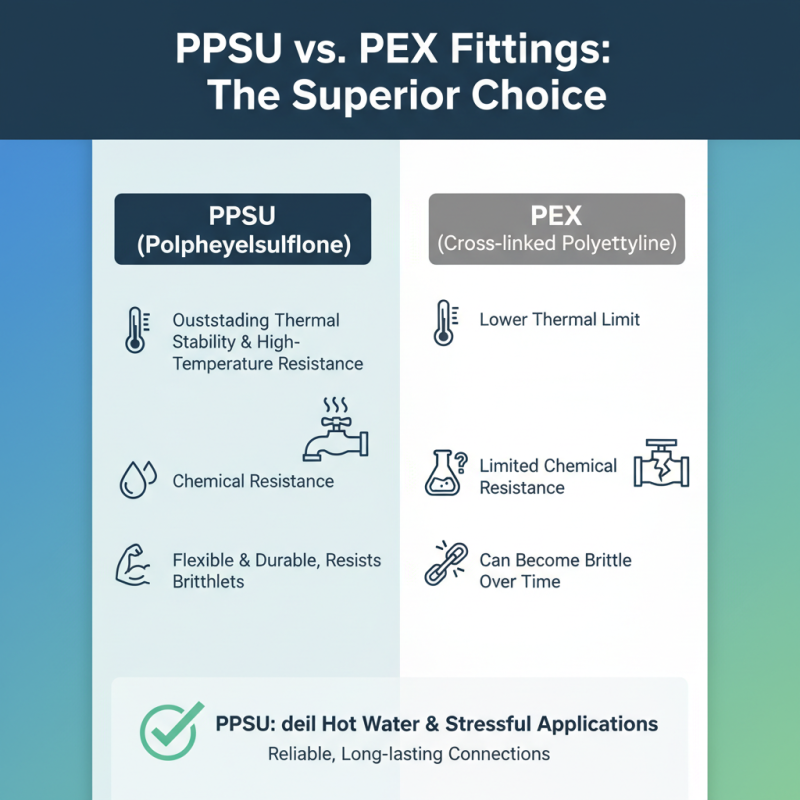

Comparative Analysis: PPSU vs. Other PEX Fitting Materials

When comparing PPSU (Polyphenylsulfone) to other PEX fitting materials, it is essential to consider the mechanical properties and chemical resistance that each material offers. PPSU stands out for its outstanding thermal stability and resistance to high temperatures, making it particularly suitable for hot water applications where other materials might fail or degrade. Unlike standard PEX fittings, which can become brittle over time, PPSU remains flexible and durable, ensuring a reliable connection even under stress.

In contrast, materials like polycarbonate or traditional brass fittings may not provide the same level of resistance to temperature fluctuations or harsh chemicals commonly found in plumbing systems. While polycarbonate can be less expensive, its susceptibility to UV degradation can lead to shortened lifespans in outdoor applications. Brass, although strong and durable, is prone to corrosion in specific environments. As a result, for long-term reliability and performance, PPSU emerges as a superior choice, especially in installations requiring high durability and resistance to varying conditions. This comparative analysis highlights the significant advantages of opting for PPSU PEX fittings in modern plumbing solutions.

Installation Best Practices for Improved Longevity of PEX Fittings

When it comes to the installation of PEX fittings, adhering to best practices is crucial for ensuring their longevity and reliability in plumbing systems. According to the Plastic Pipe and Fittings Association (PPFA), properly installed PEX fittings can last over 50 years, significantly reducing the need for frequent repairs and replacements. To achieve this durability, it is essential to follow manufacturer guidelines closely, including the use of appropriate tools and techniques during installation. Incorrect crimping or improperly sized fittings can lead to leaks, which not only compromise the efficiency of a plumbing system but can also result in costly water damage.

Temperature and pressure are also critical factors to consider when installing PEX fittings. The American Society of Plumbing Engineers (ASPE) highlights that PEX is designed to withstand temperatures ranging from -40°F to 200°F and pressures up to 80 psi in most applications. However, to maximize the lifespan of the fittings, it is recommended to avoid exposing them to extreme conditions or prolonged UV exposure, as this can lead to degradation over time. Furthermore, ensuring that the PEX is supported properly and does not experience undue movement can help prevent stress on the fittings, further enhancing their durability and reliability in residential and commercial plumbing systems.

Best Ppsu Pex Fittings Guide - Installation Best Practices

This chart illustrates the impact of various factors on the longevity of PEX fittings. Proper installation and the quality of materials used are the most significant contributors to durability, while environmental factors have a lesser impact.

Related Posts

-

Understanding the Challenges with Ppsu Pex Fittings in Modern Plumbing Solutions

-

Discover Exceptional PPSU PEX Fittings from Leading Chinese Manufacturers for Global Procurement

-

Ultimate Guide to Choosing PPSU PEX Fittings for Maximum Durability and Performance

-

2025 Top PPSU PEX Fittings Guide for Plumbing and Installation Tips

-

Unlocking the Benefits of PPSU PEX Fittings: A Modern Solution for Your Plumbing Needs

-

The Ultimate Guide to Choosing the Right Press Fittings for Your Plumbing Needs