Best Press Fittings in 2026 What to Look For?

In the rapidly evolving world of plumbing and construction, the demand for robust and reliable Press Fittings is more pronounced than ever. As we approach 2026, industry expert John Smith emphasizes, "Choosing the right Press Fittings can make or break a project." This statement rings true as professionals grapple with an array of options in a competitive market.

Press Fittings facilitate quick and efficient installations, making them an essential component in various systems. However, understanding the nuances of different products is critical. Factors such as material quality, corrosion resistance, and compatibility are pivotal. Mistakes in selection can lead to failures that compromise safety and performance.

Many still underestimate the importance of thorough research. Rushing into decisions can result in costly setbacks. The pressing demand for quality Press Fittings will continue to shape the industry landscape. By making informed choices, professionals can ensure the longevity and reliability of their installations, benefiting clients and projects alike.

Understanding Press Fittings and Their Importance in Plumbing

Press fittings play a crucial role in plumbing systems. They provide a reliable, leak-free connection between pipes. This is vital for preventing water damage in homes and buildings. The ease of installation is another benefit. Professionals and DIY enthusiasts appreciate how quickly these fittings can save time.

Understanding press fittings means recognizing their materials and applications. They are often made from durable metals, such as copper and stainless steel. Choosing the right material impacts the longevity and effectiveness of a plumbing system. Furthermore, the correct size and fitting type ensure a secure bond. However, many may overlook the importance of proper installation techniques, which can lead to future issues.

Many plumbers report that not all press fittings are created equal. Quality can vary significantly among different manufacturers. This inconsistency makes it essential to do thorough research. A little misinformation about fittings can lead to costly mistakes down the line. Tightening connections without proper tools can cause leaks or fitting damage. It's essential to reflect on past experiences to improve future practices in plumbing.

Best Press Fittings in 2026

Key Features to Consider When Choosing Press Fittings

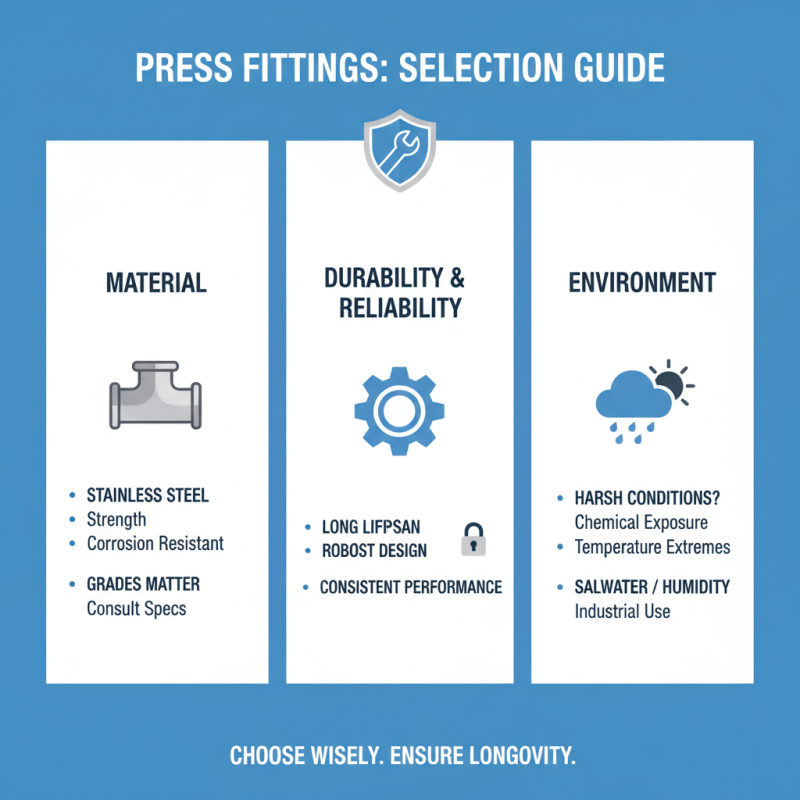

When selecting press fittings, consider key features that ensure durability and reliability. The material is crucial. Stainless steel is a common choice due to its strength and resistance to corrosion. However, not all stainless steel is equal. Some grades perform better than others. Think about the environment where these fittings will be used. Harsh conditions can impact performance.

Another important factor is the fitting design. Different systems require specific designs. Make sure the fittings can accommodate the pipes involved in your project. A snug fit is essential for preventing leaks. Some designs are more user-friendly, promoting easier installation. Investing in these can save time and reduce frustration.

Don’t forget about certifications. Reliable press fittings should meet industry standards. This ensures they have undergone rigorous testing. Check the certifications to avoid potential issues later. The market is flooded with options. Not every product will meet your expectations. Take the time to research and consult with professionals if needed. This can reduce the risk of poor decisions.

Material Options for Press Fittings: Pros and Cons

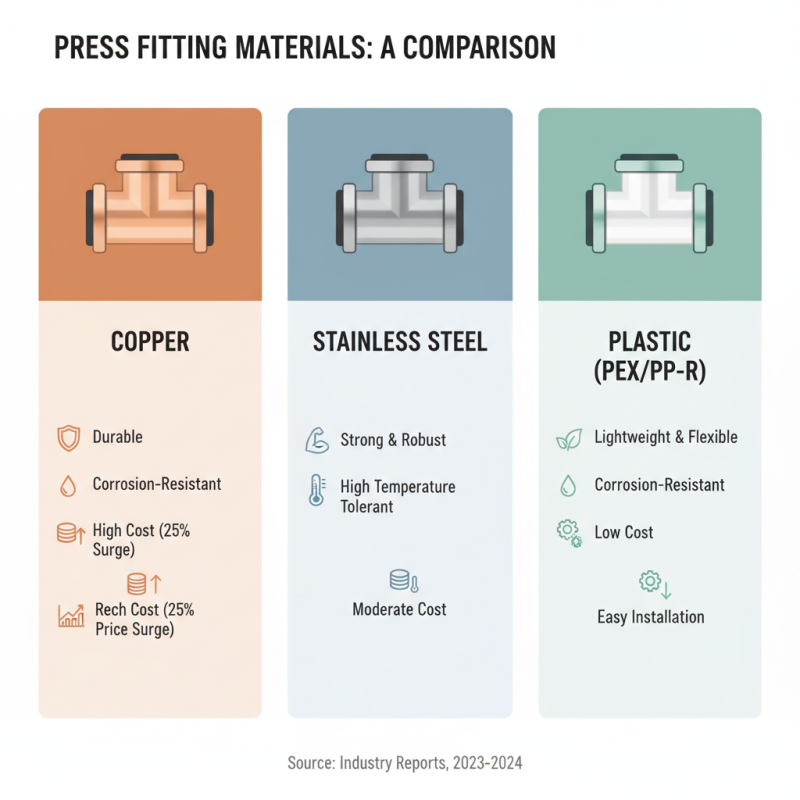

When choosing press fittings, material options play a critical role. The most common materials are copper, stainless steel, and plastic. Each has distinct pros and cons. Copper fittings are durable and resistant to corrosion. However, their cost can be relatively high, making them less appealing for large projects. Recent industry reports suggest copper prices surged by 25% in the last year, impacting budget decisions.

Stainless steel, on the other hand, offers excellent strength and longevity. It does not corrode easily, even in challenging environments. However, it can be heavier and more expensive than alternatives. In contrast, plastic fittings are lightweight and resistant to chemical damage. Yet, they may not endure high temperatures or pressure as effectively as metal options. A study by the American Society of Plumbing Engineers indicates that the demand for plastic fittings has grown by 15% annually due to cost-effectiveness.

**Tip:** Assess the working environment. If there are high temperatures or pressures, prioritize metal fittings. Consider future maintenance costs. Opt for materials that ensure longevity but fit your current budget constraints. Balancing cost with durability is crucial.

Evaluating the Best Brands for Press Fittings in 2026

When evaluating the best brands for press fittings in 2026, a few factors come into play. Quality remains a top priority. You want fittings that can withstand pressure and temperature changes. Look for materials that promise durability. Copper and stainless steel are popular choices. The finish also matters; a smooth surface can prevent leaks.

Next, consider ease of installation. Some brands may offer user-friendly designs, making setup quicker and simpler. Quick-connect features can save time on the job site. While aesthetics may seem minor, a sleek design can be appealing. However, never sacrifice functionality for looks.

Availability and support from suppliers are crucial as well. A brand that can deliver parts when needed is invaluable. Research how responsive customer service is. Customers have shared experiences of long waits for replacements. Consider these insights; they can guide your choice. Balancing quality, ease of use, and support may present challenges. It's essential to reinforce what matters most to your projects as you explore your options.

Best Press Fittings in 2026 What to Look For? - Evaluating the Best Brands for Press Fittings in 2026

| Feature | Material | Size Range (inches) | Pressure Rating (psi) | Warranty (years) | Price ($) |

|---|---|---|---|---|---|

| Corrosion Resistance | Stainless Steel | 1/2 - 4 | 2000 | 10 | 50 |

| Ease of Installation | Copper | 1/4 - 3 | 1500 | 5 | 35 |

| Versatility | CPVC | 1/2 - 6 | 1200 | 7 | 40 |

| Temperature Resistance | Brass | 1/2 - 2 | 1800 | 8 | 45 |

| Leak Proof Design | Polypropylene | 1 - 4 | 1000 | 6 | 30 |

Innovative Trends in Press Fitting Technology and Design

Innovative trends in press fitting technology are shaping the industry for 2026. The demand for reliable and efficient fittings is driving advancements in materials and design. According to recent industry reports, the use of high-strength polymers is rising. These materials offer the same durability as metal but are lighter and easier to handle.

Another aspect gaining attention is the development of smart fittings. These fittings incorporate sensors to monitor leakages and temperature changes. By providing real-time data, they enhance system efficiency. Reports indicate that smart technology can reduce maintenance costs by up to 30%.

Tips: When selecting press fittings, consider compatibility with existing systems. Look for fittings that provide ease of installation. Reliability is crucial, so prioritize those with a proven track record.

Design aesthetics are also evolving. Many manufacturers are focusing on visually appealing styles that blend with surroundings. This trend reflects a growing recognition of the importance of design in practical applications. Upgrading your fittings can improve not only functionality but also the overall ambiance of a space.

Related Posts

-

The Ultimate Guide to Choosing the Right Press Fittings for Your Plumbing Needs

-

How to Choose the Right Brass Fittings for Optimal Plumbing Efficiency

-

Discover Exceptional PPSU PEX Fittings from Leading Chinese Manufacturers for Global Procurement

-

How to Select the Best OEM Precision Parts for Your Manufacturing Needs

-

How to Choose the Right Ball Valve for Your Industrial Applications

-

How to Choose the Best Brass Elbow for Your Plumbing Needs