Why Choose OEM Precision Parts for Your Manufacturing Needs

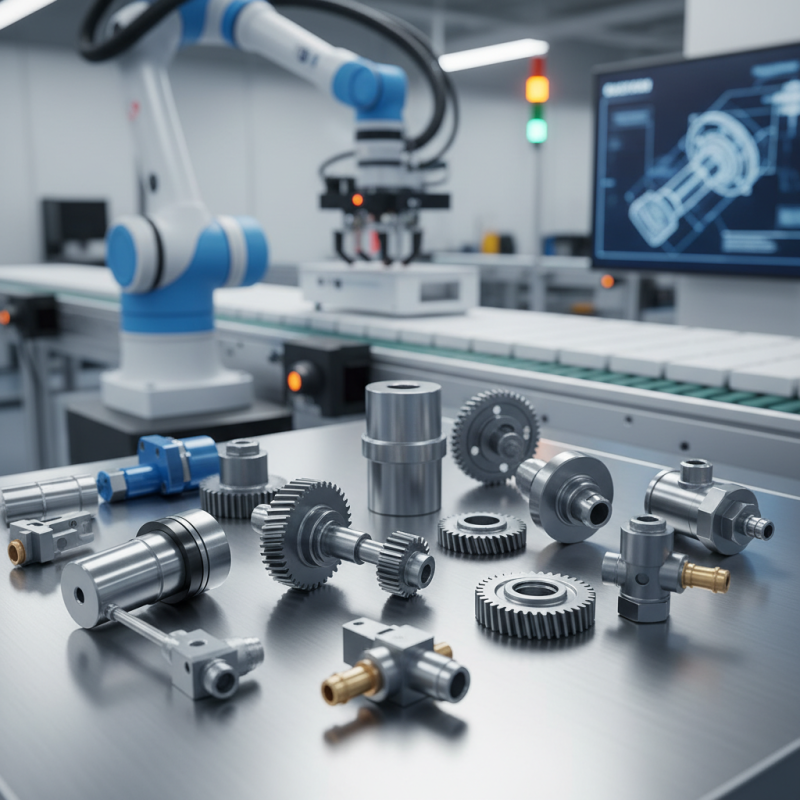

In today’s highly competitive manufacturing landscape, the choice of components can significantly influence operational efficiency and product quality. One of the most compelling options available is the use of OEM precision parts. These parts, designed and manufactured by original equipment manufacturers, offer unmatched quality and reliability tailored to meet specific industry standards. By choosing OEM precision parts, manufacturers can ensure that their products are built with components that have been rigorously tested for performance and durability.

The advantages of utilizing OEM precision parts extend beyond just quality. They contribute to streamlined production processes, reduced waste, and enhanced overall productivity. Customization options available with OEM precision parts allow manufacturers to fit components precisely to their unique specifications, further improving product integration and functionality. As manufacturers look to optimize their operations while maintaining high standards, the strategic selection of OEM precision parts emerges as a vital consideration.

In summary, integrating OEM precision parts into manufacturing processes is not just a matter of adhering to quality standards; it is a strategic decision that can have lasting implications on innovation and competitiveness in the market. Embracing OEM precision parts means investing in a future where products are not only reliable but also tailored to meet the ever-evolving needs of consumers and industries alike.

Understanding OEM Precision Parts and Their Importance in Manufacturing

Original Equipment Manufacturer (OEM) precision parts play a crucial role in the manufacturing sector, ensuring high-quality standards and efficiency in production. These parts are designed to meet specific engineering specifications, making them integral to the functionality and reliability of various applications, from automotive to aerospace.

According to a report by the National Institute of Standards and Technology, using OEM components can reduce production costs by up to 20% due to their higher tolerance and compatibility with existing systems.

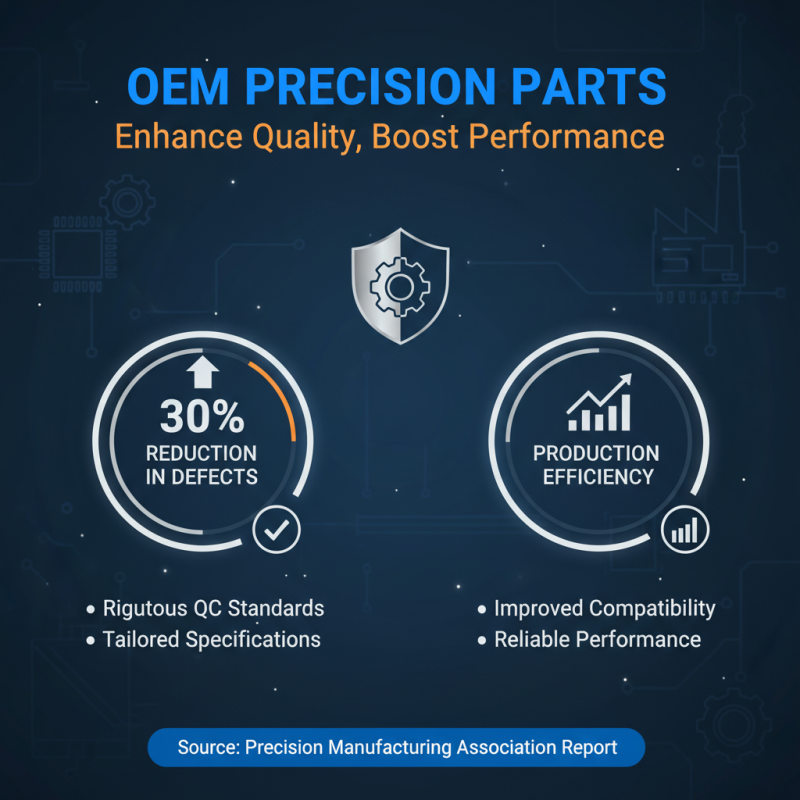

Furthermore, the importance of OEM precision parts extends to their ability to enhance product lifecycle and performance. A study conducted by the Manufacturing Institute revealed that manufacturers utilizing OEM parts experienced a 30% increase in operational efficiency. This is attributed to the reduced downtime during assembly and maintenance phases, as these parts are engineered for seamless integration. The consistent quality of OEM products also minimizes the risk of defects, which can be significantly more costly over time due to warranties and repairs.

In summary, the use of OEM precision parts is not just a matter of cost-effectiveness; it is essential for achieving optimal operational performance and longevity of products in various industries. As the manufacturing landscape continues to evolve with technological advancements, the reliance on precisely engineered OEM components will only grow stronger, underpinning the industry's commitment to excellence and innovation.

Benefits of Using OEM Precision Parts Over Generic Alternatives

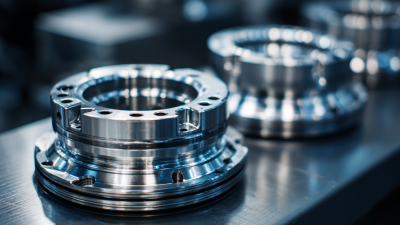

When it comes to manufacturing, the components used play a crucial role in the overall performance and longevity of products. Choosing OEM (Original Equipment Manufacturer) precision parts provides distinct advantages over generic alternatives. One of the primary benefits is the assurance of quality and compatibility. OEM parts are designed specifically for a particular system or machinery, ensuring they meet exacting standards and operational requirements. This precision minimizes the risk of malfunction, which can lead to costly downtimes and repairs in the manufacturing process.

Moreover, OEM precision parts often come with comprehensive support from the manufacturer, including warranties and technical assistance. This not only enhances reliability but also simplifies maintenance and replacement processes. In contrast, generic alternatives may lack this backing, leading to uncertainty regarding their performance and longevity. Ultimately, utilizing OEM precision parts can enhance efficiency, improve output quality, and maintain a competitive edge in an increasingly demanding marketplace. By investing in parts that are engineered for optimal performance, manufacturers can ensure that their production processes run smoothly and effectively.

Key Industries That Rely on OEM Precision Parts for Efficiency

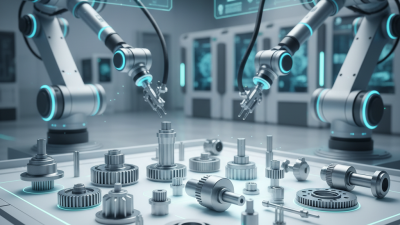

OEM precision parts play a critical role in various key industries, particularly in automotive, aerospace, and medical manufacturing. According to a report by MarketsandMarkets, the global aerospace parts manufacturing market is projected to reach $1.2 trillion by 2025, driven largely by the demand for high-quality, precise components that ensure safety and efficiency. Manufacturers in these sectors rely on OEM precision parts because they provide unmatched consistency and reliability, essential for meeting stringent safety standards.

In the automotive industry, for example, the use of OEM precision parts can lead to substantial improvements in production efficiency. A study by the Society of Automotive Engineers (SAE) highlighted that manufacturers utilizing OEM components experienced a 15% reduction in assembly time, directly correlating with increased throughput and cost savings. Furthermore, in the medical industry, where precision is paramount, the use of OEM parts enhances device reliability, ensuring products meet regulatory requirements while improving patient outcomes.

Tips: When selecting OEM precision parts, consider factors such as production volume requirements, lead times, and compatibility with existing systems. Engaging with suppliers who provide detailed specifications and quality assurances can help ensure that the parts will integrate seamlessly into your manufacturing processes. Additionally, staying informed about industry trends and advancements can provide a competitive edge in sourcing the most effective components for your needs.

Factors to Consider When Choosing OEM Precision Parts Suppliers

When selecting OEM precision parts suppliers, several factors play a pivotal role in ensuring that your manufacturing needs are met with high standards. First and foremost, assess the supplier's experience and expertise in your specific industry. A supplier with a proven track record in producing parts similar to what you require is more likely to understand your needs and deliver quality products.

Additionally, consider the supplier's production capabilities and technology. Modern manufacturing processes and equipment can significantly influence the precision and quality of the parts produced. Ensure that the supplier employs advanced technologies and adheres to stringent quality control measures. This not only guarantees product reliability but also helps in achieving better production efficiency.

**Tips:** Always ask for samples or references from previous clients to verify the quality of their work. Another important consideration is the supplier’s ability to offer customization options. This flexibility can be crucial, especially if your design specifications change or evolve over time. Keeping an open line of communication with your supplier can foster a better partnership, enabling you to address potential issues swiftly and collaboratively.

Why Choose OEM Precision Parts for Your Manufacturing Needs - Factors to Consider When Choosing OEM Precision Parts Suppliers

| Factor | Description | Importance Level |

|---|---|---|

| Quality Control | Ensures products meet strict specifications and standards. | High |

| Supplier Experience | The length of time the supplier has been in business and their industry expertise. | High |

| Lead Time | The time it takes for a supplier to deliver parts after an order is placed. | Medium |

| Production Capabilities | The ability of the supplier to produce the required parts at scale. | High |

| Customer Service | The responsiveness and support provided by the supplier. | Medium |

| Pricing Structure | The overall cost and pricing strategy of the supplier. | Medium |

| Technological Advancements | Use of modern technology in manufacturing processes. | High |

| Regulatory Compliance | Adherence to industry-specific regulations and standards. | High |

How OEM Precision Parts Enhance Product Quality and Performance

The choice of OEM (Original Equipment Manufacturer) precision parts can significantly enhance the quality and performance of your manufacturing processes. According to a recent report by the Precision Manufacturing Association, using OEM precision components reduces defects by approximately 30%, thereby increasing overall production efficiency. This improvement stems from the rigorous quality control standards and tailored specifications that OEM parts adhere to, ensuring compatibility and performance that generic components may not provide.

Moreover, OEM precision parts are designed with advanced technology that aligns closely with industry requirements. A study published in the Journal of Manufacturing Science highlights that integrating OEM components can improve the lifespan of the overall product by 25%, translating to lower replacement costs and increased customer satisfaction. High-quality materials and precision machining reduce wear and tear, thus enhancing the reliability of final products.

Tips: When selecting OEM parts, consider conducting a thorough compatibility assessment with existing machinery to ensure seamless integration. Additionally, establish a relationship with OEM suppliers who can provide comprehensive support and documentation, which is essential for maintaining quality standards in your manufacturing process.

Related Posts

-

Understanding the Role of OEM Precision Parts in Modern Manufacturing: Innovations and Impacts

-

Top 5 OEM Precision Parts for Enhanced Manufacturing Efficiency and Quality

-

2025 Top 10 Oem Precision Parts You Need for Your Business Success

-

Understanding the Unique Features of Ball Valve Types for Industrial Applications

-

Ensuring Excellence in Manufacturing Standards for Best Ppsu Pex Fittings

-

Top Stainless Steel Pipe Fittings for Your Plumbing and Industrial Needs