How to Choose OEM Precision Parts for Your Project in 2026?

In 2026, choosing OEM precision parts for your project demands careful evaluation. Various industries rely heavily on these components for quality and performance. The right OEM precision parts enhance functionality and can significantly impact your project's success.

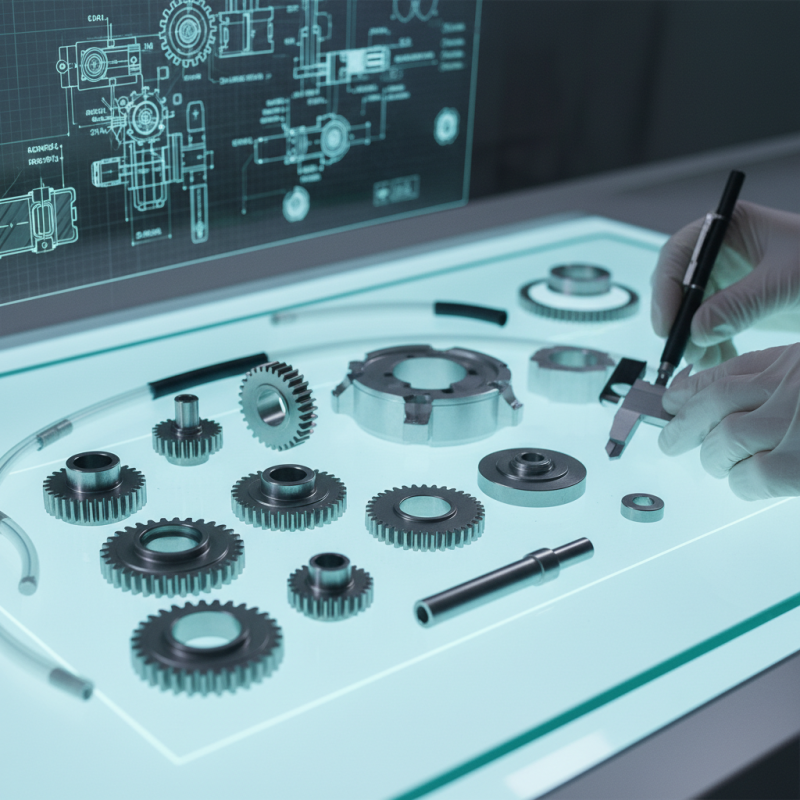

When selecting parts, consider the specifications that suit your needs. Details such as material, size, and tolerance are crucial. Ignoring these factors can lead to mismatched components, causing delays and extra costs. Evaluate potential suppliers based on their reputation, manufacturing process, and customer support. A reliable supplier can make a notable difference.

Don't rush into decisions. Take the time to compare options to find what truly meets your project's needs. Mistakes in this phase can result in wasted resources. Reflect on past experiences when selecting OEM precision parts to improve your future choices. Remember, the goal is to find parts that seamlessly integrate into your project while optimizing efficiency and effectiveness.

Understanding OEM Precision Parts: Definition and Importance

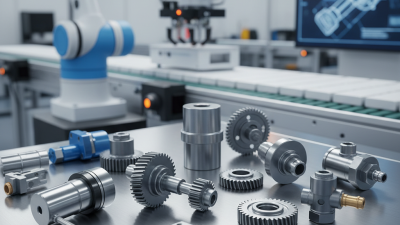

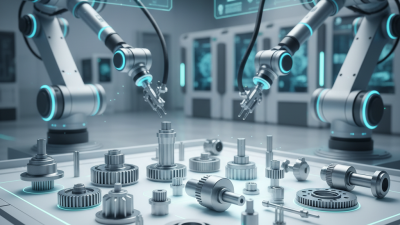

OEM precision parts play a crucial role in modern manufacturing. These components, designed specifically for original equipment manufacturers, ensure compatibility and efficiency. According to a 2022 industry report, about 70% of manufacturers rely on OEM parts for their projects. This dependence stems from the need for high-quality, reliable components that meet strict performance standards.

Understanding the definition and importance of OEM precision parts is essential. These parts are manufactured to exact specifications. This guarantees they fit seamlessly into existing systems. The consequences of choosing inferior alternatives can be significant. In fact, poor-quality parts can lead to increased downtime and higher operational costs. A study found that defects in components could increase maintenance costs by up to 30%.

Choosing the right OEM parts requires careful consideration. Compatibility with existing systems is key. A mismatched part can nullify performance benefits. It's important to assess the material quality and manufacturing process as well. Relying solely on price can be misleading. Quotations can vary widely, and the cheapest option may not always meet the required standards. Manufacturers must weigh the balance between cost and quality to avoid future setbacks.

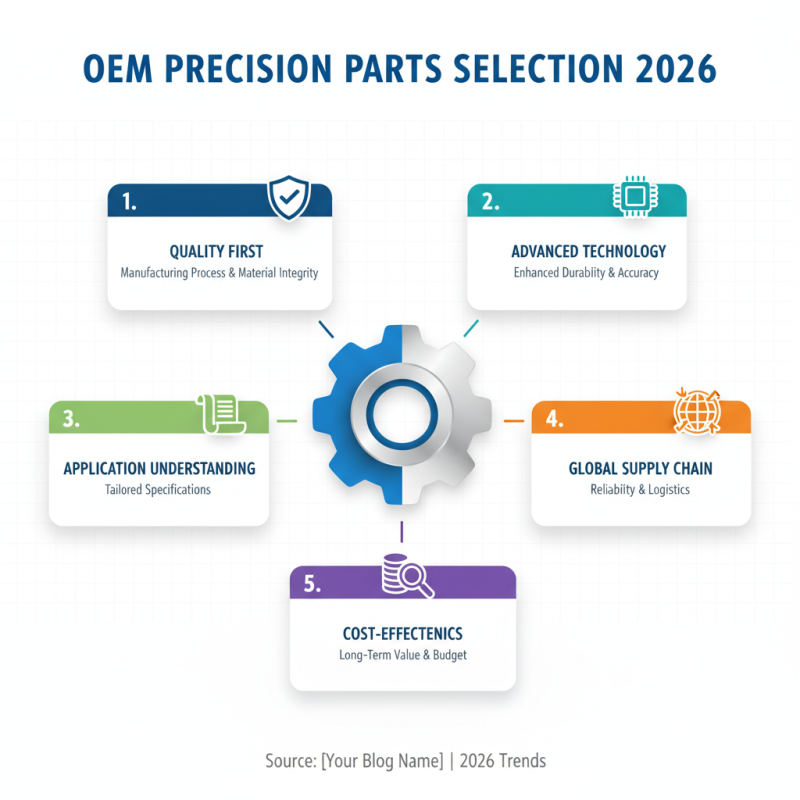

Factors to Consider When Selecting OEM Precision Parts

When selecting OEM precision parts for your project in 2026, there are several key factors to keep in mind. Quality is paramount. Evaluate the manufacturing process and material integrity. Look for suppliers who utilize advanced technologies. These can enhance the durability and accuracy of the parts. A detailed understanding of the intended application is essential. Different projects require varied specifications.

Cost is another significant consideration. While it may be tempting to opt for the cheapest option, this can lead to problems later. Assess the total cost of ownership. Higher initial costs can save expenses in the long run. Also, consider the supplier's reputation and reliability. Previous client reviews can shine a light on their performance. A sample order can be revealing. If the parts don’t match your expectations, it might lead to project delays.

Lastly, communication with potential suppliers is vital. Clear dialogue can help clarify technical requirements and delivery timelines. Misunderstandings can occur easily. Keep in mind that flexibility in negotiations can also prove beneficial. Sometimes, compromises are necessary. Reflect on what’s essential versus what’s negotiable. This balance is crucial to achieving project success.

Evaluating Material Options for OEM Precision Parts

When choosing OEM precision parts for your project, material selection is critical. Different materials offer distinct properties that can greatly affect performance. For example, aluminum is lightweight and corrosion-resistant, making it a good choice for many applications. However, it may not be suitable for high-temperature environments.

Consider steel as another option. It provides strength and durability but may add weight to your designs. Stainless steel is an alternative that balances strength and corrosive resistance. Yet, it can be more expensive and harder to machine. Evaluating these trade-offs is essential for achieving your project goals.

Using plastic composites can enhance flexibility but may lead to challenges with heat resistance. Each choice comes with advantages and drawbacks. Carefully analyze the specific needs of your project. Think about factors like stress, weight, and environmental impact. This reflection will guide you in making informed decisions that align with your project’s requirements.

Assessing Supplier Reliability and Quality Standards

When selecting OEM precision parts, supplier reliability is crucial. A reliable supplier should have a strong track record. Evaluate their production history and client feedback. A solid reputation often reflects quality work. However, don’t overlook minor complaints. Small issues can indicate larger problems.

Quality standards are another important factor. Suppliers should adhere to industry regulations. Ask for certifications related to quality management. Inspect the manufacturing processes they use. Look for advanced technology and skilled labor. Yet, sometimes, certifications can be misleading. Don’t rely solely on documents; assess real-world performance through tests.

Consider visiting the supplier’s facility. Direct interaction can reveal more than reports. Observe the working environment and the employees’ attitudes. An engaged workforce typically indicates pride in work. Be cautious, though. Sometimes, a polished exterior hides deeper issues. Take the time to ensure that the parts meet your project’s specific needs before committing.

OEM Precision Parts Supplier Reliability Assessment - 2026

This chart illustrates the assessment of various suppliers based on their reliability and adherence to quality standards as considered for selecting OEM precision parts for projects in 2026.

Budgeting for OEM Precision Parts: Cost vs. Value Analysis

When budgeting for OEM precision parts, cost and value must be carefully analyzed. It's easy to focus solely on the initial price tag. However, this approach can lead to overlooking the quality and longevity of the components. A cheaper part may save money upfront but could fail sooner, leading to increased costs down the line.

Consider the specific needs of your project. For complex applications, investing in higher-quality parts may offer significant performance advantages. Think about the total cost of ownership, including maintenance and replacement. Understanding these factors will help you make better decisions. A part that seems expensive might actually provide better value over time.

While estimating costs, don’t forget about unforeseen expenses. Pricing can fluctuate due to market demands or material shortages. Always include a buffer in your budget for unexpected situations. It’s alright to reevaluate your choices as the project progresses. Flexibility can lead to better outcomes and ensure that your project stays on track.

Related Posts

-

Explore Business Opportunities in Oem Precision Parts at 2025 China 138th Import and Export Fair

-

Why Choose OEM Precision Parts for Your Manufacturing Needs

-

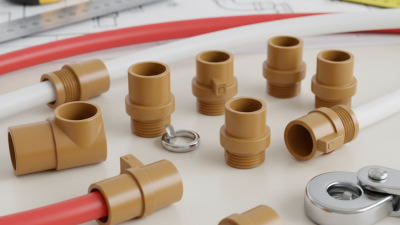

The Ultimate Guide to Choosing the Right Brass Fittings for Your Plumbing Needs

-

2025 Top PPSU PEX Fittings Guide for Plumbing and Installation Tips

-

Quick and Easy Fittings Tips for Every DIY Project

-

2025 Top 10 Oem Precision Parts You Need for Your Business Success