How to Choose the Right Ball Valve for Your Industrial Applications

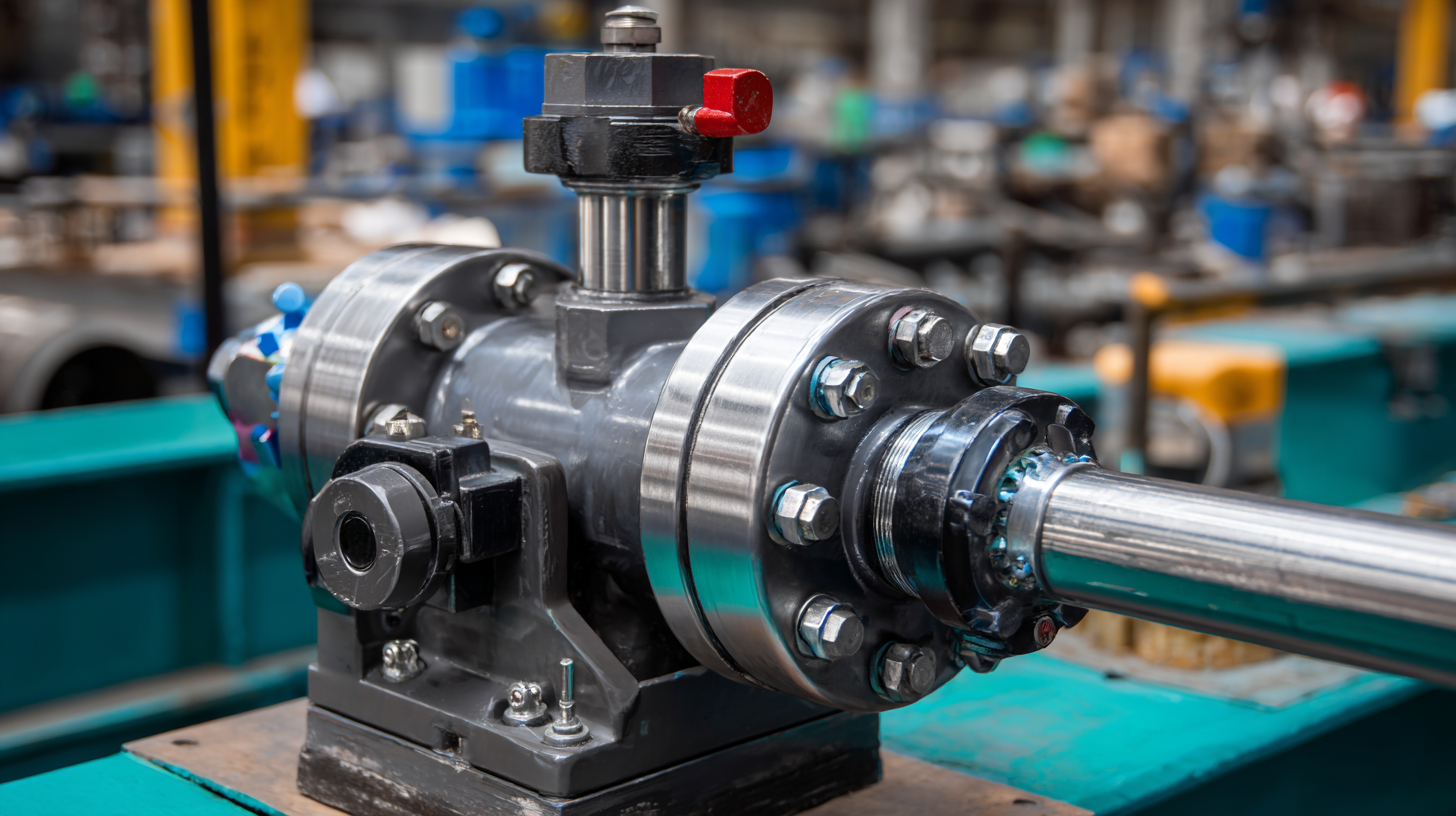

In industrial applications, the selection of the right components is crucial for ensuring efficiency and safety, and one of the most important components in fluid control systems is the ball valve. A ball valve, known for its ability to provide tight sealing and quick on/off flow control, comes in various designs and materials, each suited for specific operational requirements. Understanding how to choose the right ball valve is essential for optimizing performance and reliability in diverse industries, from oil and gas to water treatment. This guide will navigate through the vital factors to consider when selecting a ball valve, including pressure ratings, material compatibility, and valve size. By making informed decisions in the selection process, industrial operators can enhance system functionality and minimize maintenance issues, ensuring seamless operation in their processes.

Understanding Ball Valve Types and Their Applications

When selecting a ball valve for industrial applications, it is crucial to understand the different types and their specific uses. Common types include trunnion-mounted, floating, and V-ball valves, each designed for unique operational needs. According to a recent report by the Global Ball Valve Market, floating ball valves account for approximately 40% of the market due to their widespread use in industries like oil and gas, water treatment, and chemical processing. Their simple design makes them ideal for low to medium pressure applications, allowing for effectiveness in diverse environments.

On the other hand, trunnion-mounted ball valves are gaining traction in high-pressure and high-temperature environments, particularly in power generation and refining processes. With their ability to handle large volumes and provide consistent performance, trunnion-mounted options are projected to witness a growth rate of 6% annually, as noted in a study conducted by Research and Markets. Furthermore, specialty options like V-ball valves are favored for flow regulation in applications requiring precise control, often used in HVAC systems and industrial automation. Understanding these types enables industries to enhance operational efficiency and safety, ultimately selecting the most suitable ball valve for their needs.

Key Factors to Consider When Selecting a Ball Valve

When selecting a ball valve for industrial applications, several key factors must be considered to ensure optimal performance and longevity. First and foremost is the valve material—common materials include stainless steel, plastic, and brass, each chosen based on compatibility with the intended fluid and working environment. According to a report by the Global Ball Valve Market Research, 40% of failures in industrial valves are attributed to material corrosion, emphasizing the importance of choosing the right alloy to prevent premature degradation.

Another critical factor is the valve size and pressure rating. Proper sizing ensures efficient flow control and minimizes energy loss. The American Society of Mechanical Engineers (ASME) recommends that a valve's pressure rating be at least 25% higher than the maximum system pressure. Additionally, flow characteristics must be evaluated—specifically, whether a full-bore or reduced-bore valve is more appropriate for the application at hand. These considerations play a vital role in achieving reliable operation and maintaining safety standards within industrial settings.

Ball Valve Selection Criteria for Industrial Applications

Material Compatibility and Its Impact on Valve Performance

When selecting a ball valve for industrial applications, material compatibility is a crucial factor that directly influences valve performance. The materials used in the construction of a ball valve—such as stainless steel, brass, or plastic—must be compatible with the fluids they will be controlling. Using the wrong material can lead to corrosion, leakage, and eventual valve failure, which can result in costly downtime and safety hazards in an industrial setting.

Additionally, considering the chemical properties of the fluids, including temperature, pressure, and pH levels, is essential in choosing the right material. For example, corrosive substances may require valves made from specialty alloys or coatings to withstand harsh conditions. Similarly, higher temperatures may dictate the use of materials that maintain integrity under extreme heat. Therefore, a thorough analysis of the process conditions and fluid characteristics is necessary to ensure that the selected ball valve not only functions effectively but also maintains longevity and reliability in the demanding environments typical of industrial applications.

How to Choose the Right Ball Valve for Your Industrial Applications - Material Compatibility and Its Impact on Valve Performance

| Material Type | Compatibility with Fluids | Temperature Range (°C) | Pressure Rating (psi) | Typical Applications |

|---|---|---|---|---|

| Stainless Steel | Water, Oils, Gases | -40 to 200 | 1500 | Pipelines, HVAC |

| PVC | Water, Chemicals | 0 to 60 | 150 | Irrigation, Water Treatment |

| Brass | Water, Air, Oil | -20 to 180 | 300 | Automotive, Heating |

| Carbon Steel | Water, Oils | -29 to 200 | 1500 | Oil & Gas, Mining |

| PTFE | Chemicals, Pharmaceuticals | -200 to 260 | 150 | Chemical Processing |

Sizing and Flow Considerations for Optimal Valve Function

When selecting the right ball valve for industrial applications, proper sizing and flow considerations are crucial for optimal valve function. The valve size must correspond to the system's flow requirements to prevent issues such as cavitation, which can occur when there is inadequate flow through a valve, leading to damage and inefficiency. Conducting a computational fluid dynamics (CFD) analysis can help estimate localized flow patterns and assist in determining the ideal valve size for your specific application.

Tips: Always consider the size of the piping system and the flow rate when choosing a valve. Oversizing can lead to flow disturbances, while undersizing might cause pressure issues. Furthermore, evaluate the actuator options available; the right actuator will enhance the performance and response time of the valve in your setup.

Additionally, keep in mind the operational conditions, such as temperature and pressure, to ensure that the chosen valve can withstand the industrial environment. Integrating automated systems can further improve efficiency and control, offering greater reliability in maintaining optimal flow rates for your processes.

Maintenance Requirements for Different Ball Valve Types

When selecting a ball valve for industrial applications, it's essential to understand the maintenance requirements associated with different types. The industrial valve market is projected to grow significantly, with revenue expected to increase from $86.67 billion in 2025 to $131.6 billion by 2033, indicating a clear trend towards the adoption of efficient valve technologies. Various ball valve designs, such as standard, trunnion-mounted, and full-port valves, each come with specific maintenance protocols that can impact overall performance and longevity.

Tips: Regular maintenance checks can prolong the life of your ball valves. Ensure that the seating surfaces are regularly inspected and that any wear or damage is addressed promptly to avoid costly downtime. Additionally, it is crucial to consider the valve materials' resistance to the fluids handled, as this can significantly influence the maintenance cycle.

Understanding the maintenance needs of different ball valve types can also help in making informed decisions that align with industry trends. As the market evolves, the introduction of advanced materials and designs is shaping the performance benchmarks for industrial valves. Maintaining proper lubrication and monitoring for leaks are key aspects of keeping the valve systems running smoothly, especially as the industry sees an expected CAGR of 6% moving forward.

Related Posts

-

The Future of Innovation in Ball Valve Technology

-

How to Choose the Right Ball Valve for Your Industrial Needs

-

How to Choose the Right Ball Valve for Your Industrial Needs

-

Understanding the Unique Features of Ball Valve Types for Industrial Applications

-

How to Choose the Right Compression Fittings for Your Global Procurement Needs

-

Ensuring Excellence in Manufacturing Standards for Best Ppsu Pex Fittings