How to Choose the Right Brass Fittings for Your Project?

Choosing the right brass fittings is crucial for any project involving plumbing or gas. Brass fittings are durable, resistant to corrosion, and offer a reliable seal. Whether you’re a professional plumber or a DIY enthusiast, understanding your options is vital.

Consider the various types of brass fittings available. They come in many shapes and sizes. Some may not fit perfectly at first, leading to leaks or other issues. Make sure to check compatibility with your existing pipes. Your project could suffer if you pick the wrong size.

Quality is another key factor. Cheaper options may save money initially but can lead to failures later. Investing in high-quality brass fittings often pays off long-term. While it's tempting to choose based on price alone, remember that reliability is essential.

Understanding Different Types of Brass Fittings and Their Applications

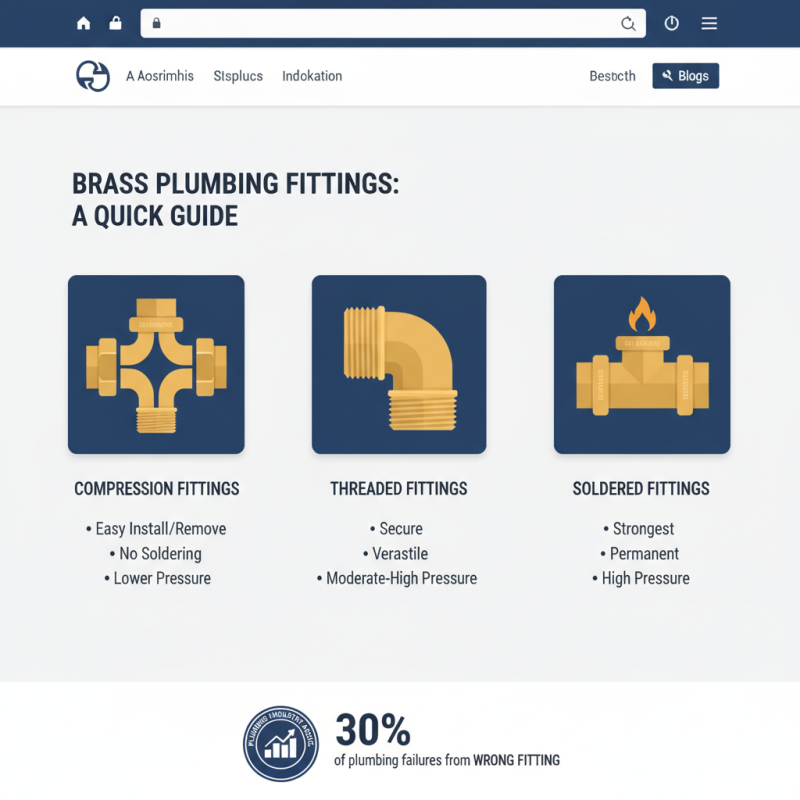

Brass fittings come in various types, each serving different functions. For plumbing, compression fittings are common. They create a tight seal without the need for soldering. They are easy to install and remove. However, they may not withstand high pressures well. A report from the Plumbing Industry Association indicates that approximately 30% of plumbing failures stem from improper fitting choices.

Another type is the threaded fitting. These are used in both water and gas applications. They provide a secure connection but can sometimes be difficult to tighten effectively. Using incorrect thread types can lead to leaks. The American Society of Mechanical Engineers notes that around 25% of leaks in gas lines result from improper fittings.

Flare fittings are also popular, especially in gas lines. They use a cone-shaped design to create a strong joint. It is essential to ensure the fittings are compatible with the tubing. Misalignment can result in failure. A study by the National Pipe Fitters Association emphasized that fitting compatibility issues lead to over 15% of installation challenges. Each type has its pros and cons. Understanding their applications is crucial for success. Choosing the right fitting can save time and resources.

Evaluating Size and Compatibility for Brass Fittings in Your Project

When selecting brass fittings, size and compatibility are crucial. Measure the diameter of your pipes accurately. Common sizes include 1/2 inch, 3/4 inch, and 1 inch. Each fitting must match the pipe size perfectly. A mismatched fitting can lead to leaks, which could be costly.

Compatibility extends beyond size. Consider the specific type of brass being used. Different applications require different alloys. For plumbing, pick fittings that resist corrosion. If your system involves high pressure, ensure the fittings can withstand that. Sometimes, people focus so much on appearance that they overlook these details.

Always double-check the thread types as well. You can find both NPT and BSP threads in brass fittings. These are not interchangeable. Using the wrong thread can damage your equipment. Test the fit of your chosen fitting before full installation. This small step can prevent major issues down the line. Remember, it's better to pause and review your choices than to rush into faulty installations.

Considering the Environmental Factors Affecting Brass Fittings Performance

When selecting brass fittings, understanding environmental factors is key. Temperature fluctuations can impact brass performance. In areas with high humidity, brass may corrode faster. Outdoor projects face additional challenges from rain and snow.

Soil conditions also play a role. In acidic or alkaline environments, brass fittings may degrade. It’s crucial to assess the local environment. Poor choices can lead to costly repairs. Often, project specifications overlook these details.

If your fittings will be submerged, consider how water chemistry affects durability. Chlorinated water can be especially harsh. Regular maintenance can help, but what if it’s neglected? Reflect on the long-term performance. Choose wisely, as these decisions greatly influence the project outcome.

Assessing Quality Standards and Certifications for Brass Fittings

When selecting brass fittings for your project, quality standards and certifications are crucial. Look for fittings that meet industry standards. This can indicate their reliability. For instance, check for certifications like ASTM or ISO. These certifications ensure that the fittings can withstand pressure and temperature variations.

Tips: Always ask for documentation when purchasing. Sometimes, sellers may not provide this upfront. Verify if the manufacturer follows quality control processes. A lack of transparency here might be a red flag.

Don't overlook the details. Inspect the finish of the brass fittings. A smooth and even surface usually signifies better quality. Rough spots might indicate poor craftsmanship. Additionally, consider the alloy composition. Higher copper content typically means better corrosion resistance.

Tips: Trust your judgment. If something feels off, take a step back. Sometimes, low prices come with hidden costs. Invest the time to assess your options. Quality fittings can save you from future headaches.

Budgeting for Brass Fittings: Cost vs. Quality Considerations

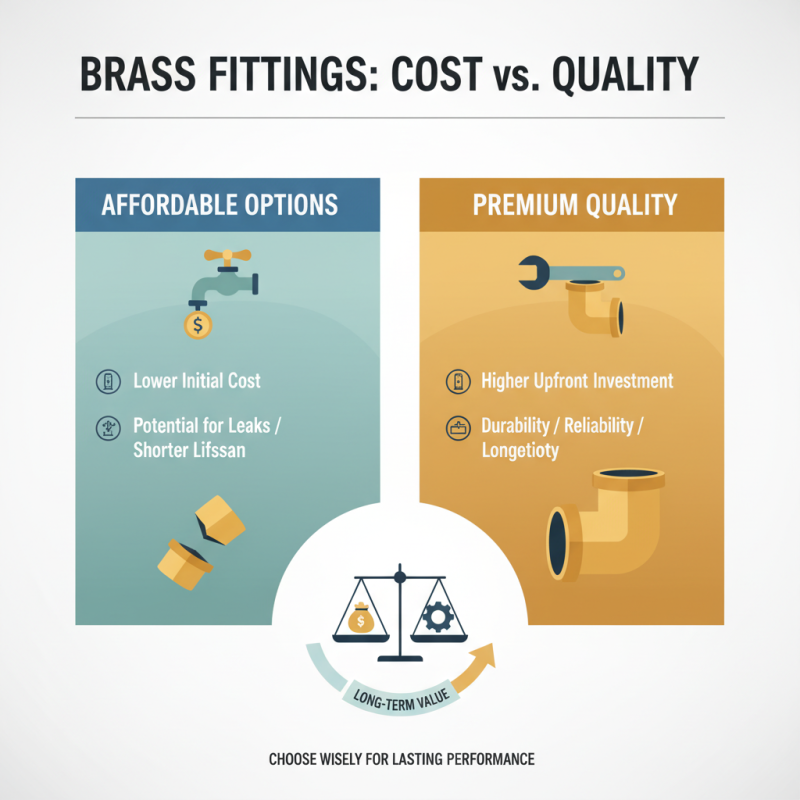

Selecting brass fittings for your project can be a balancing act between cost and quality. On one hand, there are affordable options that may seem tempting. However, cheaper fittings might compromise durability and performance. On the other hand, high-quality fittings often come with a higher price tag. It’s essential to consider the long-term implications of your choice.

Tips: Always assess the specific needs of your project. If you’re working in high-pressure environments, investing in better-quality fittings is crucial. Also, consider the lifetime of the fittings. Sometimes, the more expensive options save money in the long run through increased reliability and fewer replacements.

While budgeting, don’t forget about installation costs. Often, lower-priced fittings require more frequent maintenance, leading to hidden costs. Reflect on how these choices impact the overall budget and efficiency.

Pay attention to the materials as well. Not all brass fittings are created equal. Check the specifications and choose fittings that align with your project's demands. Sometimes, opting for a mid-range product offers a practical balance between affordability and quality. It's essential to weigh your options carefully.

Related Posts

-

The Ultimate Guide to Choosing the Right Brass Fittings for Your Plumbing Needs

-

How to Choose the Best Brass Elbow for Your Plumbing Needs

-

How to Choose the Right Brass Fittings for Optimal Plumbing Efficiency

-

Understanding the Benefits of Using Brass Elbow Fittings in Plumbing Systems

-

Understanding the Importance of Brass Elbow Fittings in Modern Plumbing Systems

-

7 Essential Tips for Sourcing High-Quality Brass Elbows in Today's Global Market