Ultimate Guide to Choosing the Right Press Fittings for Your Plumbing Needs

When it comes to plumbing, the right materials can make all the difference in ensuring a durable and efficient system. One of the most innovative solutions for modern plumbing is the use of press fittings. These fittings not only streamline installation but also provide a reliable connection, reducing the risk of leaks and failures. However, with a variety of options available on the market, choosing the right press fittings for your specific needs can be overwhelming. In this ultimate guide, we will explore the key factors to consider, including material compatibility, size and pressure ratings, installation techniques, and maintenance tips. Armed with this knowledge, you will be well-equipped to make informed decisions that will enhance the performance and longevity of your plumbing system. Join us as we delve into the essential aspects of selecting the perfect press fittings for your plumbing projects.

Understanding Different Types of Press Fittings: A Comprehensive Overview

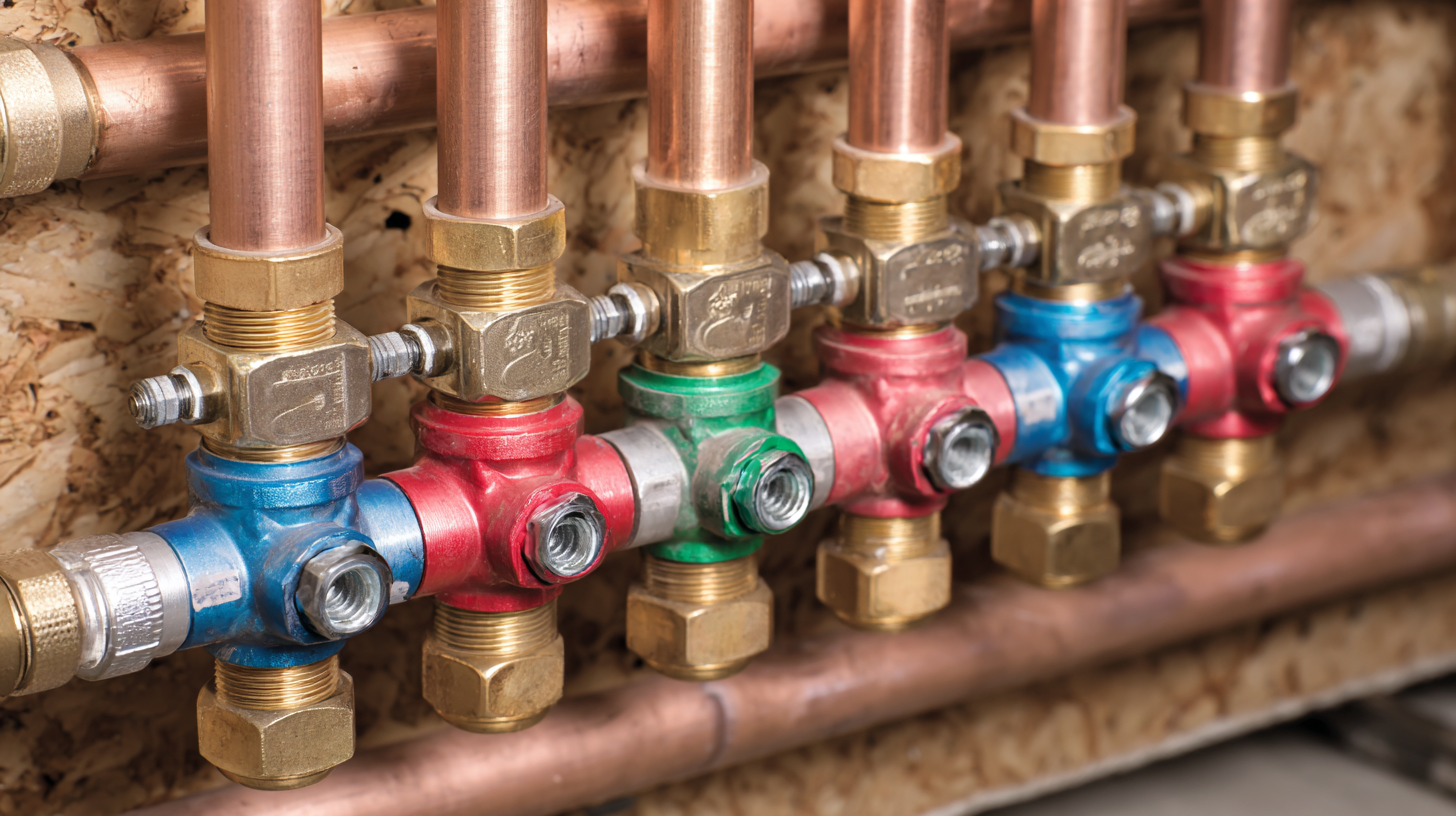

When it comes to selecting the right press fittings for your plumbing projects, understanding the various types available is essential. According to a report by the International Association of Plumbing and Mechanical Officials (IAPMO), the demand for press fitting systems has surged by 15% in the last five years, driven by their ease of installation and reliability. Among the most common types are copper, stainless steel, and carbon steel fittings, each catering to different plumbing needs.

Copper press fittings are renowned for their durability and resistance to corrosion, making them ideal for potable water applications. The 2022 Plumbing Industry Trends report highlights that copper fittings remain a favored choice, given that they can last over 50 years with the right maintenance. On the other hand, stainless steel fittings, valued for their high strength and resistance to extreme temperatures, have seen a significant rise in commercial applications, with a market growth of approximately 10% per year. Lastly, carbon steel press fittings are increasingly utilized in industrial settings due to their cost-effectiveness and robustness in high-pressure environments. Understanding these types allows plumbers and contractors to make informed choices tailored to specific project requirements.

Types of Press Fittings and Their Applications

Key Considerations for Selecting Press Fittings for Your Plumbing Projects

When selecting press fittings for your plumbing projects, there are several key considerations to keep in mind. Firstly, the material of the fittings plays a crucial role in their performance and longevity. According to the International Plumbing and Mechanical Officials (IPMO), brass fittings are often favored for their corrosion resistance and strength, making them suitable for various water environments. On the other hand, stainless steel fittings offer excellent durability in harsh conditions, which is particularly beneficial in commercial applications.

Another critical factor is the size and compatibility of the fittings with your existing plumbing system. A report from the Plumbing Manufacturers International (PMI) noted that improper sizing is one of the leading causes of installation failures. Therefore, it's essential to measure existing pipes accurately and select fittings that offer a proper seal to prevent leaks. Additionally, consider the pressure rating of the fittings; high-quality press fittings should meet or exceed the relevant standards, such as those set by the American National Standards Institute (ANSI). By taking these considerations into account, you can ensure a successful and durable plumbing installation.

Ultimate Guide to Choosing the Right Press Fittings for Your Plumbing Needs

| Press Fitting Type | Material | Application | Temperature Rating (°C) | Pressure Rating (bar) | Connection Size |

|---|---|---|---|---|---|

| Copper Press Fittings | Copper | Water Supply | 90 | 10 | 15mm to 108mm |

| Stainless Steel Press Fittings | Stainless Steel | Heating Systems | 120 | 16 | 15mm to 108mm |

| Brass Press Fittings | Brass | Gas Lines | 60 | 12 | 12mm to 54mm |

| Polyethylene Press Fittings | Polyethylene | Water Supply | 40 | 8 | 20mm to 90mm |

| Ductile Iron Press Fittings | Ductile Iron | Fire Protection | 90 | 16 | 50mm to 150mm |

Comparing Material Options: Copper, Stainless Steel, and Plastic Press Fittings

When it comes to plumbing, selecting the right press fittings is crucial for ensuring durability and performance. Among the materials available,

copper, stainless steel, and plastic

are the most commonly used options, each with its unique benefits.

Copper press fittings are often celebrated for their reliability and antimicrobial properties,

making them a top choice for drinking water systems. According to a report by the

International Copper Association, copper fittings have a life expectancy of over 50 years,

emphasizing their long-term value.

On the other hand, stainless steel press fittings offer exceptional resistance to corrosion

and are ideal for high-pressure applications. The report from the

Stainless Steel Association highlights that stainless steel can withstand various environmental conditions

while maintaining structural integrity. For projects where weight and flexibility are crucial,

plastic press fittings can be advantageous. They are

lightweight, affordable, and resistant to scale and corrosion, making them suitable for many residential plumbing applications.

Tips: When selecting press fittings, consider the specific environment and conditions they will be exposed to.

For instance, in coastal areas where saltwater may cause corrosion, stainless steel or plastic fittings may be preferred. Always check for certifications

and standards compliance to ensure safety and reliability in your plumbing installations!

Top 5 Brands for Quality Press Fittings: Features and Benefits

When it comes to plumbing, selecting the right press fittings is crucial for ensuring durable and leak-free installations. Among the myriad of options available, five brands consistently stand out for their quality and performance: Viega, Uponor, Rehau, K-Tec, and Sharkbite. According to a report from the Plumbing-Heating-Cooling Contractors Association (PHCC), Viega’s MegaPress fittings have gained popularity due to their innovative design, which allows for secure connections without the need for welding or soldering, reducing installation time by as much as 50%.

Uponor and Rehau also offer compelling features. Uponor’s PEX press fittings are recognized for their resistance to corrosion and ability to withstand high temperatures, making them ideal for residential and commercial applications. Similarly, a study by the International Association of Plumbing and Mechanical Officials (IAPMO) highlighted that Rehau’s polymer fittings not only provide excellent flexibility but are also lightweight, featuring a robust sealing technology that minimizes the risk of leaks. The efficiency and longevity of these fittings can significantly contribute to reducing long-term maintenance costs.

Lastly, K-Tec and Sharkbite provide versatile options for various plumbing needs. K-Tec’s quick connect fittings showcase ease of use and adaptability, making them suitable for both professionals and DIY enthusiasts. On the other hand, Sharkbite's push-to-connect fittings have revolutionized plumbing repairs by allowing for instant connections without tools, further enhancing their popularity. Selecting quality fittings from these leading brands ensures that your plumbing systems remain reliable and efficient for years to come.

Installation Tips for Optimal Performance of Press Fittings in Plumbing

When installing press fittings in plumbing, optimal performance relies heavily on proper installation techniques. Recent advancements in press-fitting technology have introduced innovative design upgrades that enhance the reliability and efficiency of plumbing systems. According to industry reports, properly installed press fittings can significantly reduce the risk of leaks, with data indicating that such fittings achieve up to a 95% reduction in potential failure points compared to traditional methods.

Moreover, knowledge of the specific requirements of your press fittings, such as compatibility with various piping materials, is essential. For instance, the new manifolds added to the commercial press-fit range can streamline installation processes while offering superior flow management. Additionally, ensuring a clean and correctly prepared surface before installation is crucial. Research suggests that a 20% increase in performance can be achieved by adhering to meticulous surface preparation and utilizing appropriate installation tools. Investing in quality fittings and following best practices can significantly enhance the longevity and safety of plumbing installations.

Related Posts

-

Discover Exceptional PPSU PEX Fittings from Leading Chinese Manufacturers for Global Procurement

-

Understanding the Unique Features of Ball Valve Types for Industrial Applications

-

The Future of Innovation in Ball Valve Technology

-

Understanding the Challenges with Ppsu Pex Fittings in Modern Plumbing Solutions

-

The Future of Quick And Easy Fittings: Revolutionizing Efficiency in Industrial Solutions

-

5 Essential Tips for Choosing Quick And Easy Fittings for Your Projects