Ultimate Guide to PVC Pipe Fittings Benefits Types and Uses

In the world of plumbing and construction, PVC pipe fittings have become a cornerstone due to their versatility and durability. According to industry expert John Smith, a recognized authority in plastic piping systems, "PVC pipe fittings are essential for creating reliable and lasting connections in various applications, from residential plumbing to complex industrial systems." This statement encapsulates the importance of understanding the different types, benefits, and applications of PVC fittings.

As we delve into the ultimate guide to PVC pipe fittings, it is crucial to explore their numerous advantages, such as resistance to corrosion, ease of installation, and cost-effectiveness. These attributes not only make PVC fittings a preferred choice among professionals but also contribute significantly to the efficiency of plumbing systems across various sectors. Whether you're a contractor seeking reliable materials for your next project or a DIY enthusiast looking to understand the intricacies of plumbing, this guide will provide valuable insights into selecting the right PVC pipe fittings for your needs while recognizing the impact they have on the success of any plumbing venture.

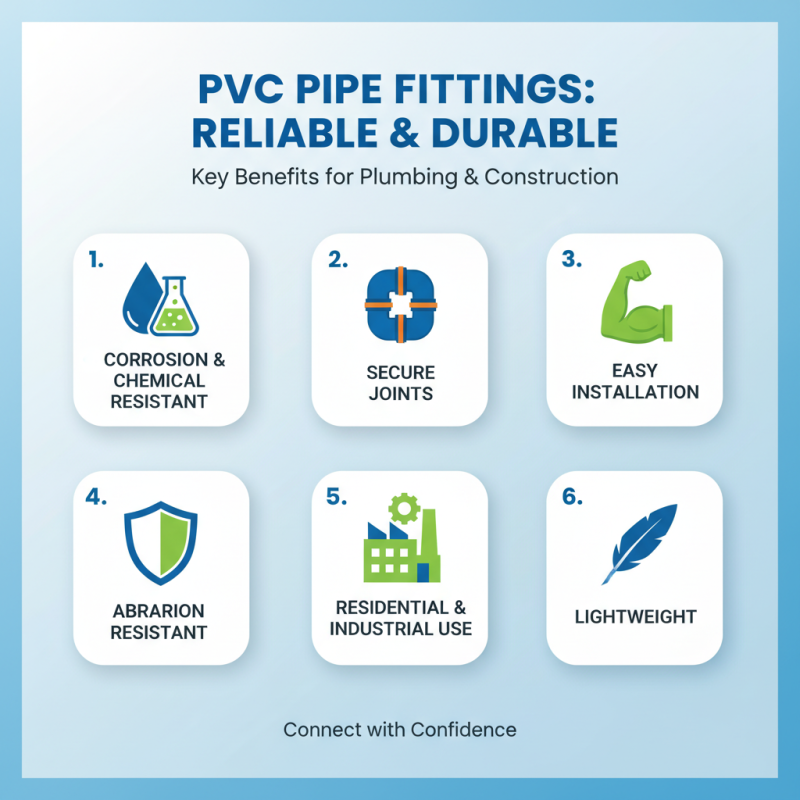

Overview of PVC Pipe Fittings and Their Importance

PVC pipe fittings play a crucial role in various plumbing and construction applications, providing a reliable and durable solution for connecting pipes and creating secure joints. Made from polyvinyl chloride, these fittings offer resistance to corrosion, chemicals, and abrasion, making them suitable for both residential and industrial use. Their lightweight nature simplifies handling and installation, allowing for quick assembly without compromising structural integrity.

The importance of PVC pipe fittings extends beyond mere functionality; they also contribute to the efficiency and longevity of plumbing systems. By enabling seamless transitions between different pipe sizes and types, these fittings ensure optimal flow rates and reduce the risk of leaks. Additionally, the variety of fittings available, such as elbows, tees, and couplings, allows for versatile configurations to meet the specific needs of any project. This adaptability, combined with excellent thermal properties, makes PVC fittings a preferred choice among professionals in the industry.

Types of PVC Pipe Fittings and Their Specific Applications

When it comes to PVC pipe fittings, understanding the types available and their specific applications is crucial for effective plumbing and construction projects. One of the most common types is the coupling, used to connect two sections of pipe, allowing for straight-line flow. Couplings come in several varieties, including slip couplings and threaded couplings, making them versatile for different circumstances.

Another significant fitting is the elbow, which enables changes in direction in a piping system; commonly available in 45-degree or 90-degree angles, elbows are essential for navigating around obstacles or creating more complex layout designs.

In addition to couplings and elbows, tees play a vital role in distributing flow from one main line to two branches. This fitting is especially useful in irrigation systems and plumbing setups where multiple outlets are required from a single pipe.

For systems that require the addition of valves, adapters serve to transition between pipe types, ensuring compatibility and functionality. Additionally, reducers allow for a seamless connection between pipes of different diameters, enabling optimal flow control and minimizing waste. Each of these fittings is designed to provide specific benefits based on the needs of the system, making an understanding of their types and applications invaluable for both professionals and DIY enthusiasts.

Benefits of Using PVC Pipe Fittings in Plumbing and Construction

PVC pipe fittings have become increasingly popular in plumbing and construction due to their numerous advantages. One of the most significant benefits of using PVC fixtures is their exceptional durability. According to the Plastic Pipe and Fittings Association (PPFA), PVC pipes have a service life of more than 50 years, making them an excellent long-term investment. They are resistant to corrosion, chemical damage, and UV radiation, which allows them to maintain their integrity in a variety of environments. This resilience leads to lower maintenance costs and improved performance, further underscoring their relevance in both residential and commercial applications.

In terms of installation, PVC fittings offer exceptional ease of use. Their lightweight composition makes them simpler to handle compared to traditional metal alternatives. The smooth inner surface of PVC provides excellent flow characteristics, which can result in enhanced energy efficiency—a critical factor highlighted in several studies. For instance, the American Society of Civil Engineers (ASCE) noted that using PVC can reduce pumping costs in plumbing systems by up to 30%. Additionally, the flexibility in design allows for a wide range of configurations, making it easier to adapt to specific project requirements without compromising integrity.

Furthermore, PVC fittings are cost-effective, contributing to reduced overall project expenses. The National Association of Home Builders (NAHB) reports that projects utilizing PVC fittings see an average reduction of 15-20% in material costs compared to metal fittings. This affordability doesn't sacrifice quality; instead, it reflects the growing trend in the industry to adopt more sustainable and efficient materials. As a result, the widespread use of PVC in various applications—from residential plumbing systems to large-scale construction projects—is expected to continue, driven by the benefits they offer.

Ultimate Guide to PVC Pipe Fittings Benefits Types and Uses

| Type of Fitting | Benefits | Common Uses |

|---|---|---|

| Elbow | Facilitates directional change in piping. | Used in plumbing systems to navigate around obstacles. |

| Tee | Allows for branch lines to be connected. | Common in water supply and drainage systems. |

| Coupling | Joins two pipes together securely. | Used to extend pipe length in plumbing and irrigation. |

| Cap | Seals the end of a pipe. | Utilized in water and waste systems to close off lines. |

| Adapter | Connects different sizes and types of pipes. | Frequently used in mixed plumbing systems. |

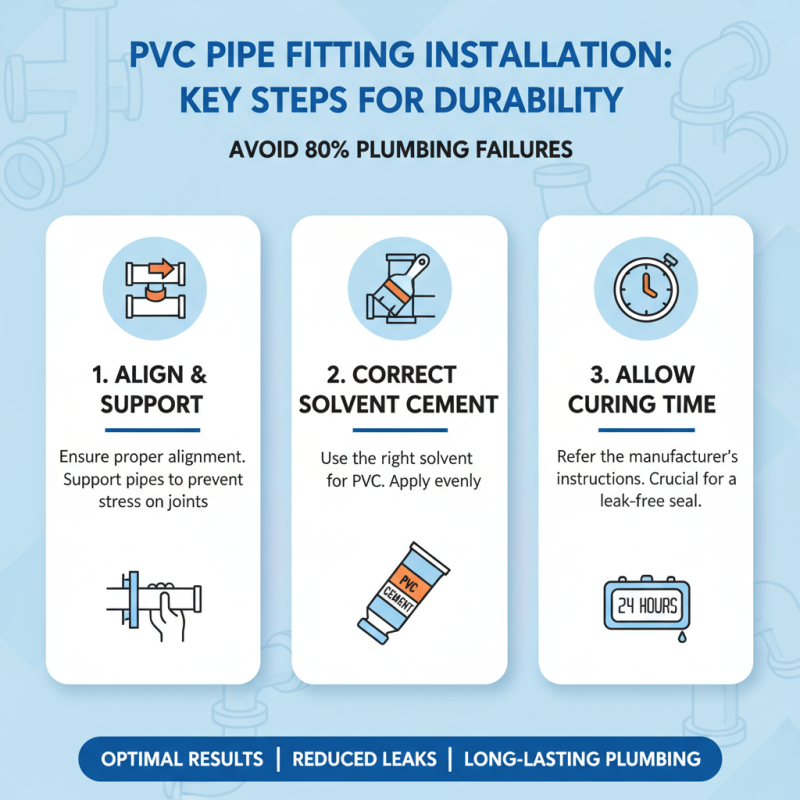

Installation Techniques for PVC Pipe Fittings and Best Practices

When it comes to the installation of PVC pipe fittings, understanding proper techniques is essential for achieving optimal results. According to industry reports, over 80% of plumbing failures are attributed to improper installation practices. To avoid such issues, it's crucial to ensure that the pipe and fittings are appropriately aligned and supported before securing them. This prevents stress on joints and potential leaks over time. Additionally, using the correct solvent cement and allowing sufficient curing time can significantly enhance the durability of the installation.

Best practices also dictate that installers should clean the surfaces of the pipe and fittings before application. A clean surface improves the bonding process, ensuring a tighter, leak-free seal. The American Society for Testing and Materials (ASTM) recommends specific cleaning agents and procedures, which have been proven to increase joint integrity by up to 30% compared to uncleaned surfaces. Moreover, employing techniques such as utilizing primer before solvent cement application can further optimize the performance of the joints, leading to a longer lifespan for the entire plumbing system. By adhering to these installation techniques and best practices, professionals can ensure that their PVC systems function efficiently and reliably for years to come.

Common Mistakes to Avoid When Using PVC Pipe Fittings

When working with PVC pipe fittings, it’s crucial to steer clear of common mistakes that can lead to ineffective installations or costly repairs. One prevalent error is the inadequate preparation of the pipe and fittings before assembly. According to the Plastic Pipe and Fittings Association (PPFA), properly cleaning and deburring the edges of PVC pipes greatly enhances the integrity of the seal. Failure to do so can result in leaks and reduced flow efficiency, undermining the very benefits PVC fittings provide.

Another mistake is improper glue application. Industry standards recommend using a primer along with the solvent cement for a reliable bond. A study conducted by the American Society for Testing and Materials (ASTM) indicated that following correct adhesive techniques can increase joint strength by up to 50%. Many users overlook the importance of adhering to cure times before applying pressure, which can jeopardize the longevity of the connection. By avoiding these pitfalls, installers can maximize the performance and durability of their PVC piping systems, leading to long-term success in their projects.

Related Posts

-

Ultimate Guide to PVC Pipe Fittings: Understanding Specifications and Industry Trends for Optimal Selection

-

Top 10 PVC Pipe Fittings You Need for Your Home Improvement Projects

-

Understanding the Role of OEM Precision Parts in Modern Manufacturing: Innovations and Impacts

-

What is Stainless Steel Pipe Fittings and Their Applications in Plumbing

-

Understanding the Unique Features of Ball Valve Types for Industrial Applications

-

5 Essential Tips for Choosing Quick And Easy Fittings for Your Projects