Quick and Easy Fittings Tips for Every DIY Project

In the world of DIY projects, mastering the art of Quick and Easy Fittings can make all the difference. Renowned expert John Smith once remarked, “The right fittings simplify your work and enhance your creativity.” This insight resonates deeply in the DIY community, where every tool and material holds the potential to transform a vision into reality.

When embarking on your next project, consider how Quick and Easy Fittings can elevate your craftsmanship. Picture yourself connecting pipes or assembling furniture without the frustration of complicated tools. Each fitting should feel natural, like a puzzle piece falling into place. However, it's crucial to remember that not every project will come together flawlessly. Mistakes happen, and those moments can lead to valuable lessons.

As you dive into your DIY journey, stay prepared for the unexpected. The best designers often find inspiration in their failures. A wrong fitting may lead you to rethink your technique, fostering creativity. Ultimately, embracing Quick and Easy Fittings means enjoying the process, learning from each attempt, and celebrating every success—big or small.

Choosing the Right Fittings for Your DIY Project

Choosing the right fittings for your DIY project can make or break your success. Many DIY enthusiasts overlook this crucial step. According to a study by the Home Improvement Research Institute, nearly 40% of DIY projects fail due to unsuitable materials. Selecting the wrong fittings may lead to leaks or structural issues. You don't want to waste time and money on a project that doesn’t hold up.

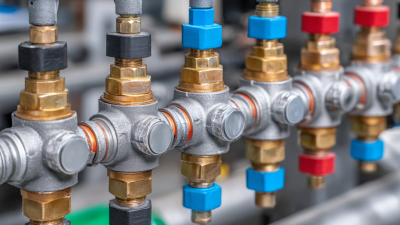

Consider the type of material you're using. Copper, PVC, and brass fittings all serve different purposes. A mismatched fitting can lead to significant problems. Industry insights suggest that starting with a clear plan greatly increases the likelihood of success. Nearly 70% of those who plan their projects report higher satisfaction. However, many don't invest the time in this step. Reflect on your choices; each fitting should align with your project goals.

Pay attention to sizes and compatibility. Measure twice, cut once, right? Yet, over 30% of DIYers still misjudge these critical dimensions. Use calipers for precise measurements. Remember, effective project management includes constant reassessment. Your fittings should not only fit physically but also functionally. Ignoring these details can result in repairs that are both frustrating and costly.

Quick and Easy Fittings Tips for Every DIY Project

Essential Tools for Installing Fittings Effectively

When tackling DIY projects, having the right tools makes a world of difference. Essential tools for installing fittings effectively include a reliable wrench, a level, and a tape measure. A wrench helps tighten fittings securely. A level ensures everything is straight. A tape measure assists in precise measurements.

Here are some tips to enhance your fitting installation experience. Always double-check your measurements before making cuts. It’s easy to make mistakes, especially when you rush. Adjustments later can be cumbersome and time-consuming. Keep your workspace organized. A cluttered area can lead to lost tools or even injury.

Also, don't forget to take breaks. Fatigue can result in careless errors. Review your progress at intervals. If something looks off, it's worth reassessing. Mistakes are part of learning, so embrace them. Keep notes on what works and what doesn't. Each project teaches you something new.

Step-by-Step Guide to Measuring and Cutting Materials

Measuring and cutting materials correctly is crucial for any DIY project. According to a recent industry report, improper measurements account for nearly 30% of project delays. Even small mistakes can lead to wasted materials and frustration. Using a reliable measuring tape can make a significant difference. Make sure to measure twice before making any cuts. This simple step can save both time and money.

When cutting materials, consider the tool you’re using. For instance, a straight edge can help ensure clean cuts, especially with wood and metal. However, even with the right tools, errors might occur. Misalignment often leads to uneven edges. It’s essential to take your time and pause to check your work. Sometimes, rushing through the process can lead to regrettable outcomes.

Additionally, measuring irregular shapes requires extra care. It's easy to overlook small details, which can affect the final fit. Surveys show that 20% of DIY enthusiasts often struggle with this aspect. Create templates or sketches. They can guide you and reduce mistakes. Reflecting on your approach can also improve your technique over time. Embrace the learning curve in DIY projects for better results.

Tips for Ensuring a Secure and Leak-Free Connection

When working on DIY projects, ensuring a secure and leak-free connection is crucial. A well-fitted joint or connection can save time and money. Start by measuring your pipes or fittings accurately. Use a rubber gasket to reinforce connections. This small addition can prevent unwelcome leaks.

Pay attention to the material of your fittings. Different materials require different approaches. Some may need Teflon tape for sealing. Others could benefit from a snug, dry fit. If you notice any corrosion or wear, don’t skip replacing the part. A tiny flaw can cause major leaks later.

Assembling your connections, be cautious with over-tightening. Too much pressure may harm the fittings. Test your connections with water before completing any project. It’s an easy step that can alert you to leaks. In hindsight, skipping this check can lead to bigger problems. Learning from these mistakes can help improve future projects.

Common Mistakes to Avoid When Working with Fittings

When working with fittings, mistakes can easily happen. One common error is neglecting to measure accurately. Taking precise measurements is crucial. An inaccurate measurement can lead to wasted materials or a poor fit. Check your measurements multiple times. It’s better to be thorough than to rush and face costly fixes later.

Another mistake is not cleaning the surfaces before attaching fittings. Dust and grime can prevent proper adhesion. Always clean surfaces with a suitable cleaner. This step might seem tedious, but it impacts the quality of the work. Skipping it could result in leaks or weak connections.

Also, using the wrong tools can cause problems. Make sure you choose tools that match the job requirements. Using the right wrench or screwdriver can make a big difference. If you struggle with a fitting, take a step back and reassess your approach. Sometimes, a minute to reflect can save hours of frustration later on.

Related Posts

-

Discover Innovative Examples of Quick And Easy Fittings Solutions

-

Unlocking Market Potential for Quick And Easy Fittings at 2025 China Import and Export Fair with Global Supply Trends

-

Ultimate Guide to Choosing the Right Pvc Pipe Fittings for Your Home Projects

-

How to Choose the Right Compression Fittings for Your Plumbing Projects

-

What is Stainless Steel Pipe Fittings and Their Applications in Plumbing

-

Mastering Stainless Steel Pipe Fittings: A Comprehensive Tutorial on Selection and Application