How to Select the Best OEM Precision Parts for Your Manufacturing Needs

In today's rapidly evolving manufacturing landscape, the demand for high-quality OEM precision parts has surged, driven by advancements in technology and increasing industry standards. Selecting the right OEM precision parts is crucial for ensuring optimal performance, efficiency, and reliability in your production processes. As we approach 2025, understanding the latest industry trends and innovations becomes even more essential for manufacturers looking to maintain a competitive edge. This blog will guide you through the critical factors to consider when choosing OEM precision parts tailored to your specific manufacturing needs.

Whether it's about material selection, supplier evaluation, or cost-effectiveness, we will explore strategies that will empower you to make informed decisions and enhance your overall manufacturing capability.

Understanding OEM Precision Parts and Their Importance in Manufacturing

When it comes to manufacturing, selecting the right OEM precision parts is essential for ensuring product quality and operational efficiency. OEM (Original Equipment Manufacturer) precision parts are specifically designed to meet the manufacturer's standards and are crucial in maintaining the integrity of the final product. Understanding their importance can significantly enhance your production process, especially in industries like automotive and aerospace, where precision and quality are paramount.

One key tip for selecting the best OEM precision parts is to assess the materials used. With the automotive sector increasingly favoring lightweight metals such as aluminum alloys, carbon fiber composites, and high-strength steel, make sure the parts you choose align with modern manufacturing trends aimed at improving fuel efficiency and meeting stringent emissions regulations.

Additionally, consider the supplier's reputation and their ability to provide consistent quality. Building relationships with established OEM manufacturers can ensure that you receive parts that not only meet your specifications but also contribute to the long-term success of your product development. Always evaluate suppliers on their quality control processes and their experience within your specific industry to secure the best outcomes.

Key Factors to Consider When Choosing OEM Precision Parts

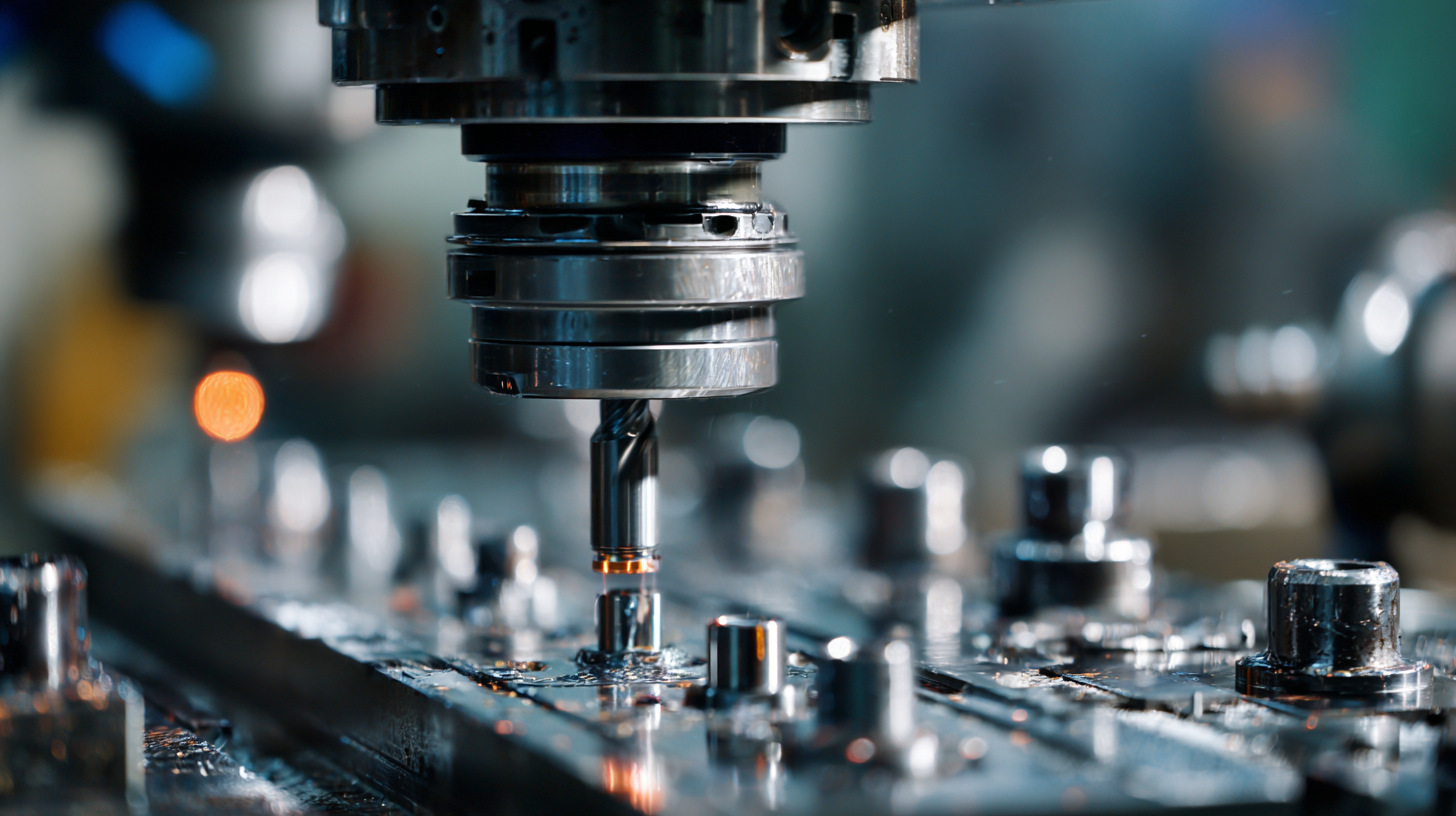

When selecting OEM precision parts for manufacturing, several key factors should be carefully evaluated to ensure optimal performance and compatibility with your specific needs. First and foremost, consider the material quality and manufacturing processes involved. The durability and functionality of precision parts are heavily influenced by the materials used, making it essential to choose suppliers that adhere to stringent quality standards. Additionally, the production techniques employed, such as CNC machining or additive manufacturing, can significantly impact the precision and reliability of the components.

Another critical factor to assess is the supplier's reputation and track record in the industry. Collaborating with a supplier who has demonstrated success in providing high-quality precision parts, especially in the context of rapidly growing sectors like the automotive industry, can minimize risk and ensure your project meets time-sensitive requirements.

As the automotive wheel rim market is expected to grow substantially, selecting an OEM that can efficiently scale production to meet demand without compromising quality will be paramount. Understanding these key considerations will enable manufacturers to make informed decisions when choosing OEM precision parts.

Types of OEM Precision Parts Available in the Market

When selecting OEM precision parts for your manufacturing needs, it’s essential to understand the different types available in the market to make an informed choice. One of the most common types is CNC machined parts, which are known for their high precision and adaptability. These parts are crafted from various materials, including metals and plastics, and are ideal for applications requiring intricate designs and tight tolerances.

Another crucial category is injection molded parts, which are frequently used in mass production due to their efficiency and cost-effectiveness. This method allows for quick fabrication of complex shapes, making it a popular choice for large-scale manufacturing. Additionally, stamped parts offer durability and are often made from sheets of metal. This technique is particularly beneficial for components that need to withstand significant stress and wear.

Lastly, 3D printed OEM parts are increasingly gaining traction in the industry. Their ability to produce highly customized components with shorter lead times makes them a valuable option for businesses looking to innovate rapidly. By understanding these various types of OEM precision parts, manufacturers can better align their selections with specific project requirements and performance expectations.

Types of OEM Precision Parts Available in the Market

Evaluating Quality and Performance Standards for OEM Parts

When selecting OEM precision parts for manufacturing, evaluating quality and performance standards is pivotal to ensure product reliability and efficiency. According to a 2022 report by the Precision Manufacturing Association, nearly 70% of organizations cited part quality as a critical factor impacting operational success. This underscores the necessity for rigorous assessments of materials, tolerances, and production processes that meet both industry norms and customer specifications.

One key metric to consider is the ISO 9001 certification, which guarantees that suppliers adhere to recognized quality management principles. Research shows that companies with ISO-certified suppliers experience up to a 30% reduction in defects and a significant improvement in on-time delivery rates. Additionally, performance standards such as ASTM and SAE ratings can provide benchmarks for material properties and mechanical performance, ensuring that OEM parts not only fit but also function optimally within their designated applications. By prioritizing these quality measures, manufacturers can enhance productivity and ensure the longevity of their products.

Building Strong Relationships with OEM Suppliers and Manufacturers

Building strong relationships with OEM suppliers and manufacturers is essential for any business looking to procure precision parts. Establishing trust and open communication can lead to better collaboration, ensuring that your specific manufacturing needs are met effectively. It's important to identify suppliers who align with your goals and values, as this can lead to improved product quality and innovation.

Tip 1: Invest time in regular communication with your suppliers. Schedule routine check-ins to discuss ongoing projects, share feedback, and explore new opportunities. This not only fosters transparency but also gives you insights into their capabilities and any potential challenges they may face.

Tip 2: Create long-term partnerships by demonstrating loyalty and commitment to your OEM suppliers. When you show that you value their contributions, you're more likely to receive priority service, competitive pricing, and better access to new technologies.

By prioritizing relationship-building with your OEM partners, you can ensure that your manufacturing processes are efficient and that the precision parts you receive meet the highest standards.