What is Stainless Steel Pipe Fittings and Their Uses?

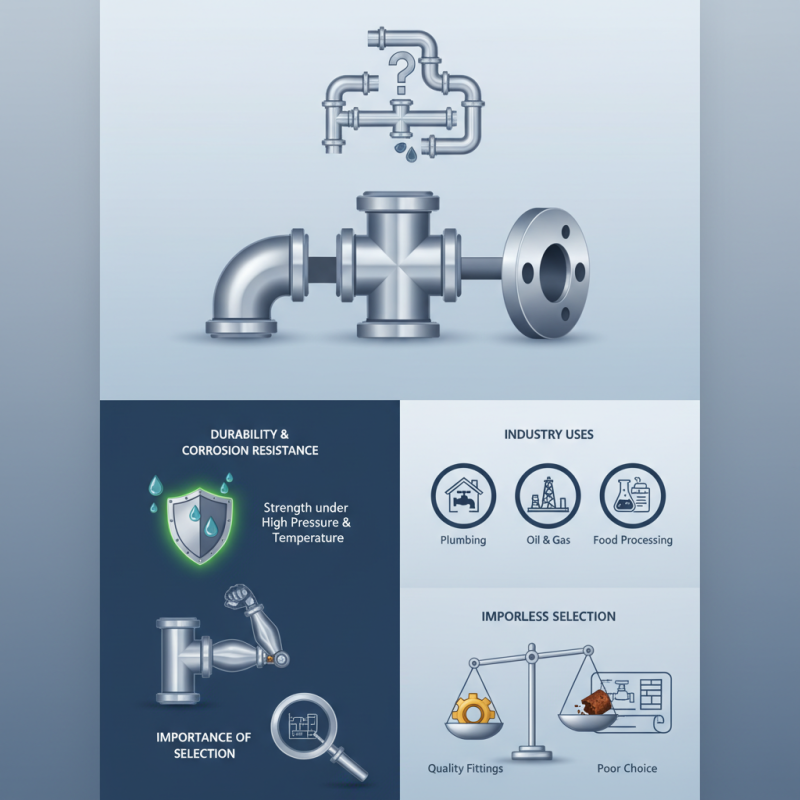

Stainless Steel Pipe Fittings are essential components in various piping systems. They connect pipes, valves, and other equipment. These fittings offer durability and corrosion resistance. Common types include elbows, tees, and flanges. They find use in diverse industries such as plumbing, oil and gas, and food processing.

In construction and manufacturing, the selection of Stainless Steel Pipe Fittings is crucial. Their reliability ensures efficient flow and reduces leaks. The material's strength withstands high pressures and temperatures. However, not all fittings are created equal. Some may corrode under specific conditions, leading to failures. Users must consider the environment and application.

Many people underestimate the importance of choosing the right fitting. A poor choice can result in costly repairs and downtime. Ultimately, understanding Stainless Steel Pipe Fittings is vital for both professionals and DIYers. Investing time in research pays off. Quality fittings are worth the expense, ensuring long-term success in any project.

What is Stainless Steel Pipe Fittings?

Stainless steel pipe fittings are essential components in plumbing and industrial applications. They connect pipes, allowing fluid movement. These fittings are typically made from stainless steel due to its resistance to corrosion and durability. Reports indicate that the global stainless steel pipe fittings market is projected to reach USD 12 billion by 2027, growing at a CAGR of 5.2%. This growth reflects their increasing usage in various sectors.

The versatility of stainless steel makes it ideal for different environments. For instance, in water supply systems, these fittings help maintain water quality. They are also widely used in chemical processing industries. The ability to withstand extreme temperatures makes them reliable. However, proper installation is critical. A small error can lead to leaks or failures.

Tips:

Always ensure compatibility between fittings and pipes. Use appropriate sealing methods to avoid leaks. Regular maintenance can prevent corrosion over time. Pay attention to installation instructions; they are crucial for reliability.

Stainless steel pipe fittings play a vital role in efficiency. However, they can be costlier than other materials. This may not suit every budget. Material choices should be made carefully, considering both performance and cost.

What is Stainless Steel Pipe Fittings and Their Uses?

| Fitting Type | Description | Common Uses | Material Grade |

|---|---|---|---|

| Elbow | A pipe fitting that allows for a change in direction. | Used in plumbing and piping systems to redirect flow. | 304, 316 |

| Reducer | A fitting that decreases the diameter of a pipe. | Used to connect pipes of different sizes. | 304, 316 |

| Tee | A fitting that allows for a branch connection. | Common in water supply and drainage systems. | 304, 316 |

| Cap | A fitting used to close off the end of a pipe. | Used to seal the end of piping systems. | 304, 316 |

| Flange | A flat piece used to connect pipes or pipes to other equipment. | Used in mechanical and plumbing applications for secure connections. | 304, 316 |

Types of Stainless Steel Pipe Fittings and Their Characteristics

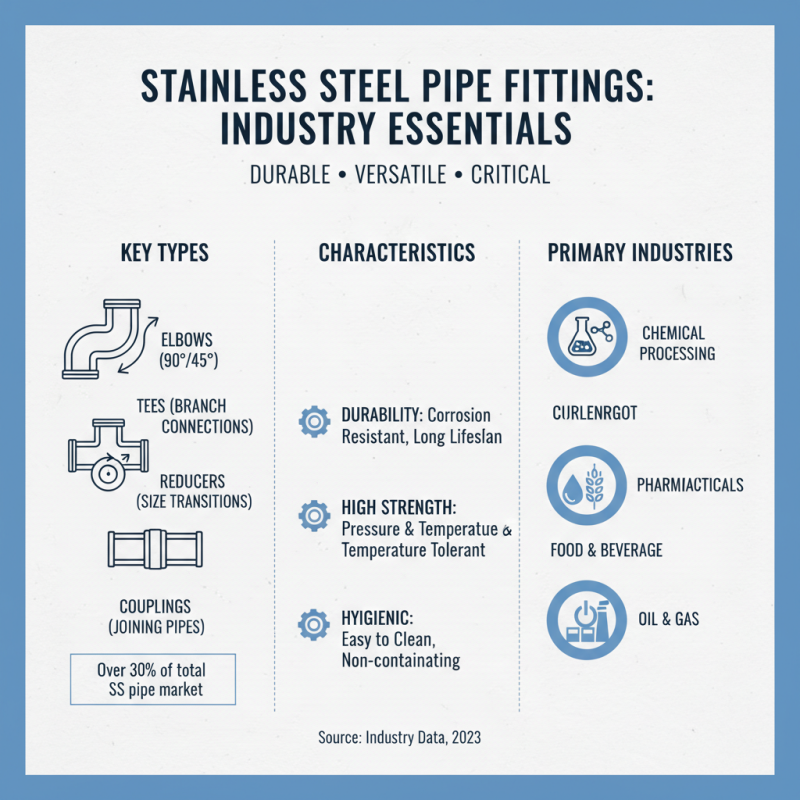

Stainless steel pipe fittings are essential in various industries. They come in different types, each with unique characteristics. Common types include elbows, tees, reducers, and couplings. According to industry data, these fittings represent over 30% of the total stainless steel pipe market. Their durability makes them popular in chemical and food processing industries.

Elbows are often used to change the direction of piping. They can be 45 or 90 degrees. This flexibility allows engineers to design efficient systems. Tees provide branching options for pipes. They can optimize flow and reduce pressure drops. Reducing fittings enable transitions between different pipe sizes. Proper selection is vital for maintaining system integrity.

Corrosion resistance is a critical feature of stainless steel fittings. However, if improperly installed, they can fail. Misalignment can lead to leaks and increased maintenance costs. Regular inspections help prevent these issues. A study found that over 20% of fittings failed due to poor installation practices. Understanding each type and its application can enhance performance and longevity.

Common Applications of Stainless Steel Pipe Fittings in Various Industries

Stainless steel pipe fittings are crucial components in various industries. Their resistance to corrosion makes them ideal for harsh environments. These fittings are used in plumbing, gas supply, and food processing. In the oil and gas sector, stainless steel fittings can endure high pressure and temperature. According to industry reports, the demand for stainless steel pipe fittings is expected to grow by 5% annually over the next five years.

In food processing, cleanliness is vital. Stainless steel is non-reactive, which helps maintain food safety. It’s used in tanks, valves, and other components. Similarly, in chemical manufacturing, these fittings prevent contamination. The durability and strength of stainless steel ensure longevity in these systems.

**Tip:** Always check the quality certification of stainless steel fittings. This ensures they meet industry standards for safety and performance. Even slight defects can lead to failures in critical applications.

Environmental factors also play a role in choosing fittings. Stainless steel can withstand extreme conditions. However, some fittings may still corrode if not maintained properly. Regular inspections are essential to ensure reliability. Maintaining these fittings can save costs in the long run.

Usage of Stainless Steel Pipe Fittings Across Industries

Advantages of Using Stainless Steel Pipe Fittings Over Other Materials

Stainless steel pipe fittings are essential in various industries. They provide strength and durability, making them a popular choice. In fact, the global market for stainless steel pipe fittings is expected to reach USD 12 billion by 2025, according to industry reports.

One key advantage of stainless steel pipe fittings is their resistance to corrosion. Unlike other materials, stainless steel can withstand harsh environments. For example, it's commonly used in chemical plants and marine applications. Studies show that stainless steel fittings can last up to three times longer than plastic or carbon steel alternatives. This longevity translates to lower maintenance costs.

However, there are some challenges. Stainless steel can be more expensive upfront. The higher cost might deter some businesses. Additionally, welding or machining stainless steel requires specialized skills. If not handled correctly, the quality can suffer. In some cases, that can lead to leaks or failures. Therefore, while stainless steel fittings offer many benefits, careful consideration is necessary before choosing them.

Maintenance and Care Tips for Stainless Steel Pipe Fittings

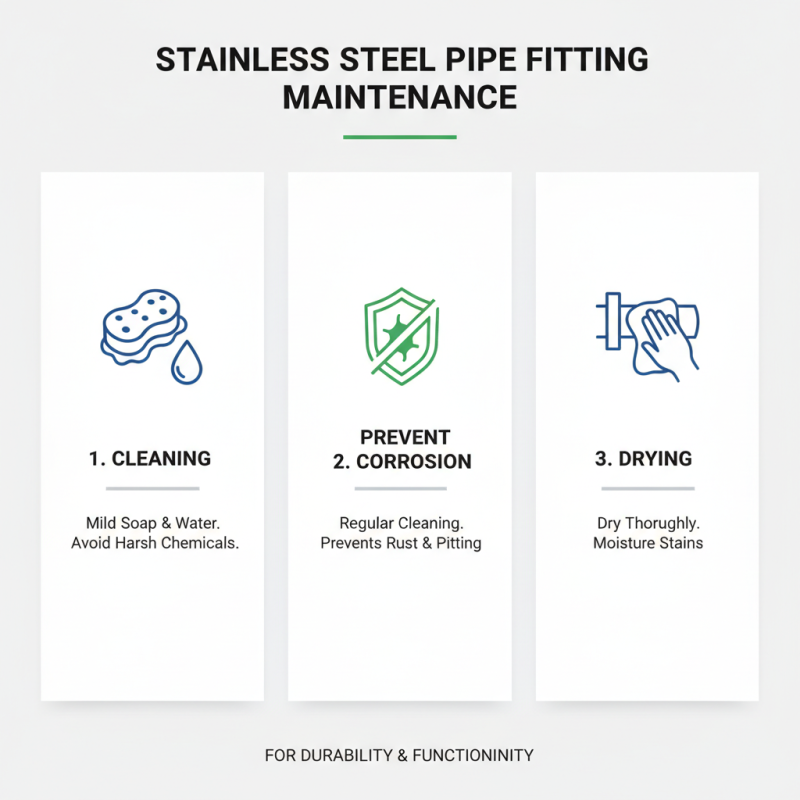

Maintaining stainless steel pipe fittings is essential for durability and functionality. Regular cleaning helps prevent rust and corrosion. Use mild soap and water for routine cleaning. Avoid harsh chemicals that can damage the finish. After cleaning, dry the fittings thoroughly. Moisture can lead to staining or pitting over time.

Inspecting the fittings periodically is also crucial. Look for signs of wear or damage. Check for leaks in joints and connections. If you notice any issues, address them promptly before they worsen. Tightening loose connections can prevent larger problems later on.

Sometimes, even well-maintained fittings can develop minor flaws. A small scratch may not seem significant, but it can harbor moisture. Ensure you regularly check for such imperfections. Keeping a maintenance log can help track the condition of your fittings over time. Some tasks may seem tedious, but attention to detail pays off in the long run.

Related Posts

-

Top 10 Stainless Steel Pipe Fittings for Your Plumbing Needs

-

Why Choosing the Right Ball Valve Can Enhance Your Industrial Efficiency and Reduce Costs

-

The Ultimate Guide to Sourcing High-Quality Brass Fittings for Your Business Needs

-

The Future of Quick And Easy Fittings: Revolutionizing Efficiency in Industrial Solutions

-

The Future of Innovation in Ball Valve Technology

-

Discover Innovative Examples of Quick And Easy Fittings Solutions