2025 Top 10 Oem Precision Parts You Need for Your Business Success

In the competitive landscape of manufacturing and production, leveraging the right components can make a significant difference in achieving business success. As we look ahead to 2025, the need for high-quality OEM precision parts is more critical than ever. These components not only enhance the functionality and reliability of your products but also play a crucial role in maintaining cost-effectiveness and operational efficiency. Each part is meticulously crafted to meet the specific demands of your industry, ensuring that your operations run smoothly and your end products meet the highest standards.

This article delves into the top 10 OEM precision parts that you should prioritize for your business in the coming year. Whether you are involved in automotive, aerospace, or other manufacturing sectors, understanding which components to focus on can streamline your processes and provide a competitive edge. With advancements in technology and an increased emphasis on quality and precision, these parts are vital for driving innovation and optimizing performance. Embrace these essentials as we guide you through the significant role that OEM precision parts will play in shaping the future of your business.

Top 10 OEM Precision Parts Driving Efficiency in Manufacturing by 2025

As we look towards 2025, the manufacturing industry is set to witness a transformation driven by the adoption of OEM precision parts that enhance efficiency and productivity. According to a recent report by MarketsandMarkets, the global precision parts manufacturing market is projected to reach $98 billion by 2025, fueled by advancements in technology and increasing demand for high-quality components across various sectors. This growth highlights the critical role that OEM precision parts play in optimizing manufacturing processes and reducing downtime.

Among the top OEM precision parts expected to drive this efficiency are precision machined components, which are crucial for industries ranging from aerospace to automotive. A study by Deloitte indicates that manufacturers who invest in precision engineering can reduce production errors by up to 50%, thereby lowering costs and improving time-to-market. Furthermore, with the integration of IoT technologies, companies can achieve real-time monitoring of part quality and machine performance, leading to a more responsive and adaptable manufacturing environment. By prioritizing these OEM precision parts, businesses can not only enhance their operational efficiency but also position themselves competitively in an evolving market landscape.

Key Innovations in CNC Machining: The Future of Precision Parts

The future of precision parts manufacturing is being reshaped by key innovations in CNC machining and digital manufacturing technologies. Industry reports indicate that the global CNC machine market is expected to surpass $100 billion by 2025, driven by the increasing demand for high-precision components across various sectors such as aerospace, automotive, and medical devices. These advancements not only enhance production capabilities but also enable manufacturers to achieve tighter tolerances and improve overall product quality.

Embracing new, environmentally friendly machining solutions is critical for businesses aiming to maintain a competitive edge. Recent findings suggest that automation in CNC machining can lead to a productivity boost of up to 30%, as companies transition from traditional operational methods to automated systems. This shift not only reduces labor costs but also minimizes waste and energy consumption, reflecting a growing commitment to sustainability within the manufacturing sector. As industries strive for greater efficiency and environmentally responsible practices, investing in the latest CNC technologies will be essential for business success in the coming years.

2025 Top 10 Oem Precision Parts You Need for Your Business Success - Key Innovations in CNC Machining: The Future of Precision Parts

| Part Name | Material | Precision Level | Lead Time (Days) | Key Innovations |

|---|---|---|---|---|

| Precision Gear | Aluminum Alloy | ±0.01 mm | 30 | Advanced Tooth Design |

| Connector Housing | Polycarbonate | ±0.02 mm | 25 | Injection Molding Optimization |

| Precision Shaft | Stainless Steel | ±0.005 mm | 20 | Laser Machining Technology |

| Cooling Plate | Copper | ±0.03 mm | 15 | Enhanced Thermal Conductivity |

| Support Bracket | Carbon Steel | ±0.1 mm | 40 | Robotic Welding Integration |

| Custom Valve | Brass | ±0.02 mm | 35 | 3D Printing Techniques |

| Sensor Housing | Aluminum | ±0.01 mm | 28 | Surface Treatment Innovations |

| Medical Component | Titanium | ±0.005 mm | 45 | Biocompatible Innovations |

| Tool Holder | High-carbon Steel | ±0.02 mm | 50 | Precision Heat Treatment |

| Automotive Bracket | Mild Steel | ±0.05 mm | 55 | Cost-effective Fabrication |

The Role of Additive Manufacturing in Enhancing OEM Precision Component Production

Additive manufacturing, commonly known as 3D printing, is revolutionizing the production of OEM precision components, driving both cost efficiency and innovation. According to a report by Wohlers Associates, the additive manufacturing industry has surpassed $12 billion in revenue and is projected to grow annually by more than 25% over the next five years. This growth underscores the significant advantages that additive processes offer, such as reduced lead times and the ability to create complex geometries that traditional manufacturing methods struggle to achieve.

Typically, in industries such as aerospace and automotive, the precision and reliability of components are paramount. The latest studies indicate that additive manufacturing can enhance the overall performance of these components by allowing for customized designs that meet specific operational requirements. For instance, GE has successfully employed 3D printing to produce fuel nozzles with optimized designs that not only reduce weight but also improve fuel efficiency, capturing a competitive advantage in the market. As businesses increasingly adopt these technologies, the role of additive manufacturing in enhancing OEM production quality and efficiency will be pivotal in ensuring their long-term success.

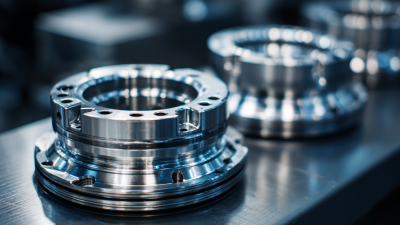

Exploring Material Trends: How Advanced Alloys Impact OEM Part Quality

The impact of advanced alloys on OEM (Original Equipment Manufacturer) part quality cannot be overstated. As businesses strive for precision and durability in their components, the choice of materials plays a crucial role.  Advanced alloys, characterized by their unique properties, enable manufacturers to create parts that withstand extreme conditions while maintaining high performance. For instance, titanium alloys are gaining traction due to their exceptional strength-to-weight ratio and corrosion resistance, making them ideal for aerospace and automotive applications.

Advanced alloys, characterized by their unique properties, enable manufacturers to create parts that withstand extreme conditions while maintaining high performance. For instance, titanium alloys are gaining traction due to their exceptional strength-to-weight ratio and corrosion resistance, making them ideal for aerospace and automotive applications.

In addition to enhancing performance, the use of advanced alloys can lead to innovation in design and functionality. These materials often provide greater flexibility in manufacturing processes, allowing for more complex geometries and reduced waste. Furthermore, the evolution of alloy compositions, such as the incorporation of lightweight metals or composites, contributes to energy efficiency and sustainability, aligning with global business trends. By embracing these material advancements, companies can not only elevate the quality of their OEM parts but also secure a competitive edge in an increasingly demanding market.

Integrating IoT in Precision Manufacturing: Smart Parts for Smarter Businesses

The integration of Internet of Things (IoT) in precision manufacturing is revolutionizing the industry, providing businesses with unprecedented levels of efficiency and data-driven insights. According to a report by McKinsey, IoT technology could potentially unlock up to $1.2 trillion in economic value within the manufacturing sector by 2030. This transformation is largely driven by smart parts that are embedded with sensors and connectivity capabilities, enabling manufacturers to monitor processes in real-time, predict maintenance needs, and enhance overall production quality.

Moreover, the implementation of smart manufacturing technologies is not just about operational efficiency; it also supports enhanced decision-making strategies. A study from Gartner indicates that organizations utilizing IoT solutions report a 15% increase in overall productivity and a significant reduction in downtime costs. Precision parts equipped with IoT connectivity can transmit data from the production line, allowing for quick adjustments and optimizations. As businesses continue to embrace these smart solutions, those that prioritize IoT integration will likely gain a competitive edge in an increasingly data-centric marketplace.

Related Posts

-

How to Select the Best OEM Precision Parts for Your Manufacturing Needs

-

Top 5 OEM Precision Parts for Enhanced Manufacturing Efficiency and Quality

-

How to Choose the Right Brass Fittings for Optimal Plumbing Efficiency

-

How to Choose the Right Ball Valve for Your Industrial Applications

-

What are the Benefits of Using PVC Pipe Fittings in Modern Plumbing Solutions

-

Ultimate Guide to Choosing the Right Pvc Pipe Fittings for Your Home Projects