Top Stainless Steel Pipe Fittings for Your Plumbing and Industrial Needs

When it comes to plumbing and industrial applications, the selection of materials can significantly impact the efficiency and longevity of systems. Among the various options available, **Stainless Steel Pipe Fittings** stand out for their durability, corrosion resistance, and versatility. These fittings are essential components that facilitate the seamless connection of pipes, ensuring a reliable flow of liquids and gases in a variety of settings, from residential plumbing to complex industrial facilities.

The popularity of stainless steel in pipe fittings is attributed to its ability to withstand harsh conditions, including high temperatures and corrosive environments. As industries seek to enhance operational performance and reduce maintenance costs, the demand for quality stainless steel fittings continues to grow. This article will explore the top stainless steel pipe fittings available on the market today, highlighting their features, benefits, and applications to help you make informed decisions for your plumbing and industrial needs. Whether you are a contractor, engineer, or DIY enthusiast, understanding the best choices in stainless steel fittings is crucial for achieving optimal results in your projects.

Understanding Stainless Steel Pipe Fittings: An Overview

Stainless steel pipe fittings play a critical role in both plumbing and industrial applications, providing reliable connections that withstand high pressure and corrosive environments. According to a report by Grand View Research, the global stainless steel pipe fittings market was valued at approximately USD 8.3 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 6.4% from 2022 to 2030. This growth is driven by increasing demand in sectors such as oil and gas, chemicals, and building and construction, highlighting the essential nature of these fittings in various systems.

Understanding the types of stainless steel used in these fittings is crucial. For instance, austenitic stainless steels, such as grades 304 and 316, are favored for their excellent corrosion resistance and formability. The American Society for Testing and Materials (ASTM) specifies various standards for these materials, ensuring their durability and performance under different environmental conditions. Furthermore, the World Pipeline's report emphasizes that stainless steel’s longevity significantly reduces maintenance costs, making it a practical choice for long-term infrastructure projects. As industries seek efficiency and sustainability, the choice of high-quality stainless steel pipe fittings will remain a key consideration in plumbing and industrial applications.

Types of Stainless Steel Pipe Fittings for Various Applications

When it comes to plumbing and industrial applications, stainless steel pipe fittings play a crucial role due to their durability and resistance to corrosion. There are several types of stainless steel pipe fittings, including elbows, tees, reducers, and caps, each designed for specific functions. According to a recent industry report by Grand View Research, the global stainless steel pipe fittings market was valued at $2.31 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. This growth is driven by increasing investments in infrastructure and industrialization, particularly in emerging economies.

Elbows and tees are among the most commonly used fittings, essential for directing fluid flow in pipelines. For instance, 90-degree elbows are perfect for changing the direction of piping, while tees allow for branching off into different lines. Additionally, reducers are vital in systems where the flow needs to transition from one pipe diameter to another, ensuring efficiency and maintaining pressure. As per the latest report from Research and Markets, the demand for these fittings in the oil and gas sector is expected to surge, driven by the sector's requirement for robust and reliable components in high-pressure environments.

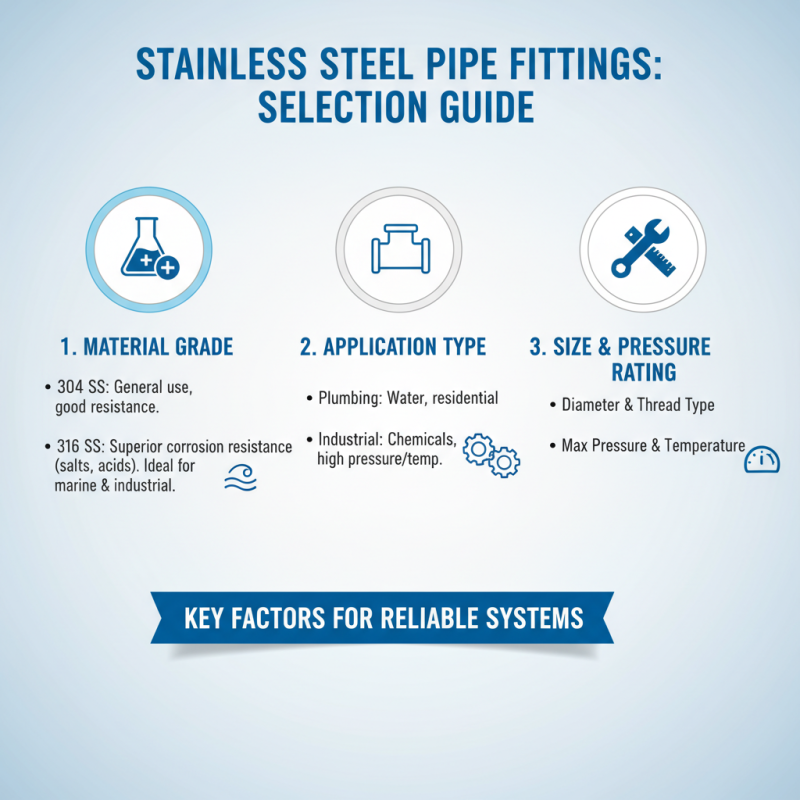

Factors to Consider When Choosing Stainless Steel Pipe Fittings

When selecting stainless steel pipe fittings for plumbing and industrial applications, several key factors come into play. First and foremost, the type of stainless steel is crucial, as different grades offer varying levels of corrosion resistance and strength. Common grades include 304 and 316, with 316 being preferable for more corrosive environments due to its enhanced resistance to salt and other aggressive substances.

Another factor to consider is the fitting's size and compatibility with existing piping systems. Proper sizing ensures that there are no issues with flow rates or pressure drop, which can be detrimental to system performance. Additionally, it’s essential to select fittings that adhere to relevant industry standards and certifications, ensuring safety and reliability in your installations.

**Tips:** Always consult with a professional to determine the right grade and size for your specific application. Additionally, when purchasing stainless steel fittings, check for warranties or guarantees from suppliers to protect your investment in case of defects. Regular maintenance and inspections can also prolong the lifespan of your fittings, ensuring smooth operation in the long run.

Benefits of Using Stainless Steel Pipe Fittings in Plumbing Systems

Stainless steel pipe fittings are increasingly favored in plumbing systems due to their durability and resistance to corrosion. Unlike other materials, stainless steel can withstand harsh environments, making it an ideal choice for both residential and industrial applications. The high strength of stainless steel ensures that pipe fittings can endure high pressures and temperatures, which is essential for maintaining the integrity of water and gas supply systems. This robustness translates to lower maintenance costs and a longer lifespan for plumbing components, reducing the need for frequent replacements.

Additionally, stainless steel is a hygienic option, particularly important in plumbing systems that transport drinking water or food products. It does not leach chemicals or flavors into liquids, ensuring that water remains pure and safe for consumption. Furthermore, its aesthetic appeal and resistance to staining make stainless steel fittings a visually pleasing choice for exposed areas. The combination of these properties not only enhances functionality but also adds value to plumbing projects, paving the way for the growing popularity of stainless steel fittings in modern construction and industrial applications.

Maintenance Tips for Stainless Steel Pipe Fittings in Industrial Settings

Maintaining stainless steel pipe fittings in industrial settings is crucial for ensuring longevity and optimal performance. Regular inspections should be conducted to check for signs of corrosion, wear, or leakage. Attention to the connection points and seals is particularly important, as these are often the most vulnerable areas. If any damage is detected, timely repairs or replacements should be made to prevent further deterioration and costly failures.

In addition to inspections, proper cleaning protocols must be established to keep the fittings in top condition. Using mild detergents and avoiding abrasive materials can help preserve the integrity of the stainless steel surface. Regular lubrication can also reduce friction at joints and prevent wear over time. Implementing these maintenance practices will not only enhance the durability of the pipe fittings but also contribute to the overall efficiency of the plumbing system in industrial applications.

Top Stainless Steel Pipe Fittings for Your Plumbing and Industrial Needs - Maintenance Tips for Stainless Steel Pipe Fittings in Industrial Settings

| Fitting Type | Size Range ( inches ) | Material Grade | Common Applications | Maintenance Tips |

|---|---|---|---|---|

| Elbow | 1/2 - 12 | 304, 316 | Piping systems, HVAC | Regular inspection for corrosion, clean with mild detergent. |

| Tee | 1/2 - 12 | 304, 316 | Water supply, drainage | Keep dry and check joints for leaks periodically. |

| Coupling | 1/2 - 12 | 304, 316 | Join pipes, hydraulic systems | Inspect for tightness and wear regularly. |

| Nipple | 1/2 - 12 | 304, 316 | Connecting two fittings | Lubricate threads to prevent seizing. |

| Cap | 1/2 - 12 | 304, 316 | End of pipe closure | Ensure a secure fit and check for rust. |

Related Posts

-

Mastering Stainless Steel Pipe Fittings: A Comprehensive Tutorial on Selection and Application

-

The Ultimate Guide to Choosing the Right Stainless Steel Pipe Fittings for Your Projects

-

Ultimate Guide to Choosing the Right Press Fittings for Your Plumbing Needs

-

Exploring the Impact of Stainless Steel Pipe Fittings on Industrial Efficiency and Durability

-

Essential Checklist for Choosing the Right Brass Elbow for Your Project

-

The Ultimate Guide to Choosing the Right Press Fittings for Your Plumbing Needs