How to Choose the Right Brass Fittings for Your Project?

Choosing the right brass fittings for your project can significantly impact functionality and durability. In the plumbing and construction industries, brass fittings account for over 30% of all metal fittings used. They are preferred for their corrosion resistance and strength. Reports indicate that the global brass fittings market is projected to grow by a CAGR of 5.2% from 2021 to 2026.

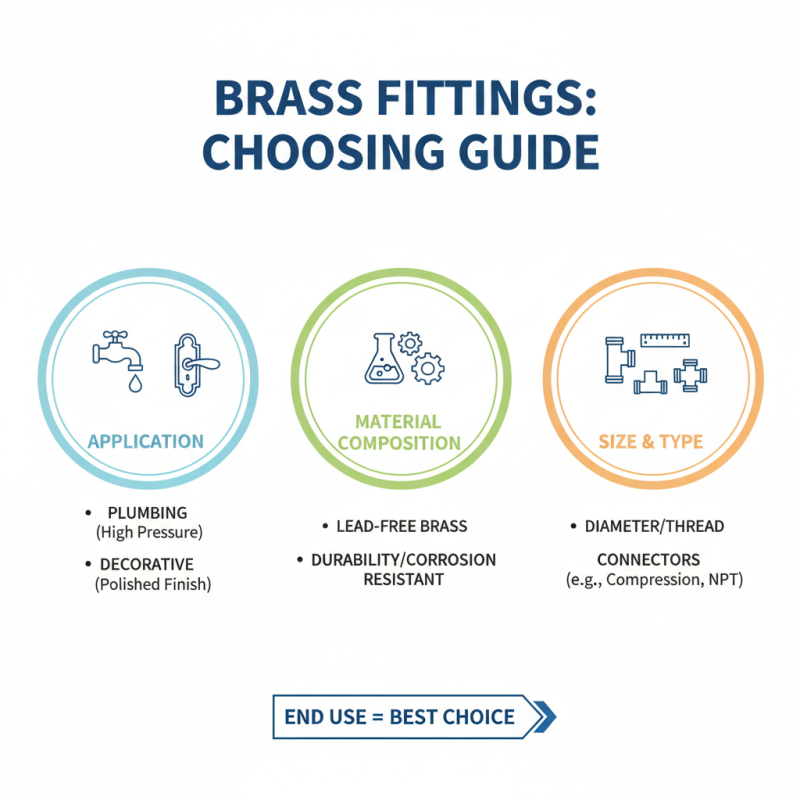

When selecting brass fittings, consider the specific application. Different projects require different sizes, shapes, and connector types. For instance, a leaking fitting can lead to costly repairs and damage. It’s crucial to avoid settling for generic products. You need to assess whether a standard fitting meets your requirements. Sometimes, opting for a higher-quality fitting may provide better long-term value.

It’s common to overlook the importance of compatibility. Not all brass fittings work well with every type of piping. Proper research and careful selection can prevent future issues. Consider factors like pressure ratings and environmental conditions. If these details are ignored, you may face significant challenges in your project.

Understanding the Importance of Brass Fittings in Plumbing Projects

Brass fittings play a crucial role in plumbing projects. They connect pipes, fixtures, and valves, ensuring a tight seal and efficient flow. The right choice of brass fittings can greatly impact the longevity of your plumbing system. When selecting these components, consider the size and type of your pipes. Mismatched fittings can lead to leaks and costly repairs.

Tips: Always measure your pipes accurately before purchasing fittings. An improper fit can cause frustration and waste time. Don’t overlook the importance of quality. Low-quality brass may corrode and fail sooner than expected, leading to leaks.

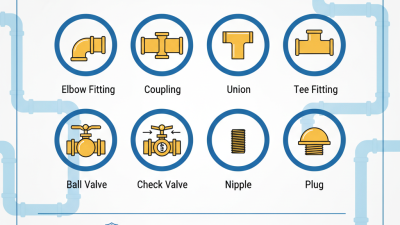

Understanding the various types of brass fittings is essential. You’ll find elbows, tees, and couplings, each serving a specific purpose. Think about the pressures and temperatures in your system. High-pressure environments require robust fittings. It's also vital to check local codes for acceptable materials. Sometimes, what works for one project may not be suitable for another.

Tips: Consider the environment where the fittings will be used. Humidity, temperature variations, and exposure can affect performance. Don’t forget to inspect your existing fittings. Look for signs of wear or corrosion. This can prevent future plumbing issues and save you money.

Factors to Consider When Selecting Brass Fittings for Your Needs

When choosing brass fittings, several factors must be considered. The application plays a crucial role. For plumbing projects, you might need fittings that can withstand high pressure. On the other hand, decorative purposes might require a more polished appearance. Understanding the end use helps narrow down your options.

Another important factor is compatibility with existing materials. Not all brass fittings work with every pipe or hose type. Improper fitting can lead to leaks and failures. A careful check is essential. Sizing also matters significantly. Measure the diameter and length accurately. An ill-fitting part is prone to issues. Don't overlook the environmental conditions. Humidity and temperature affect brass's longevity.

Lastly, quality varies among fittings. Some options may look great but fail under pressure. Always inspect for byproducts like corrosion. Reflect on your choice before finalizing it. Each detail can impact your project's success. Think about how these decisions affect your work in the long run.

Different Types of Brass Fittings and Their Applications

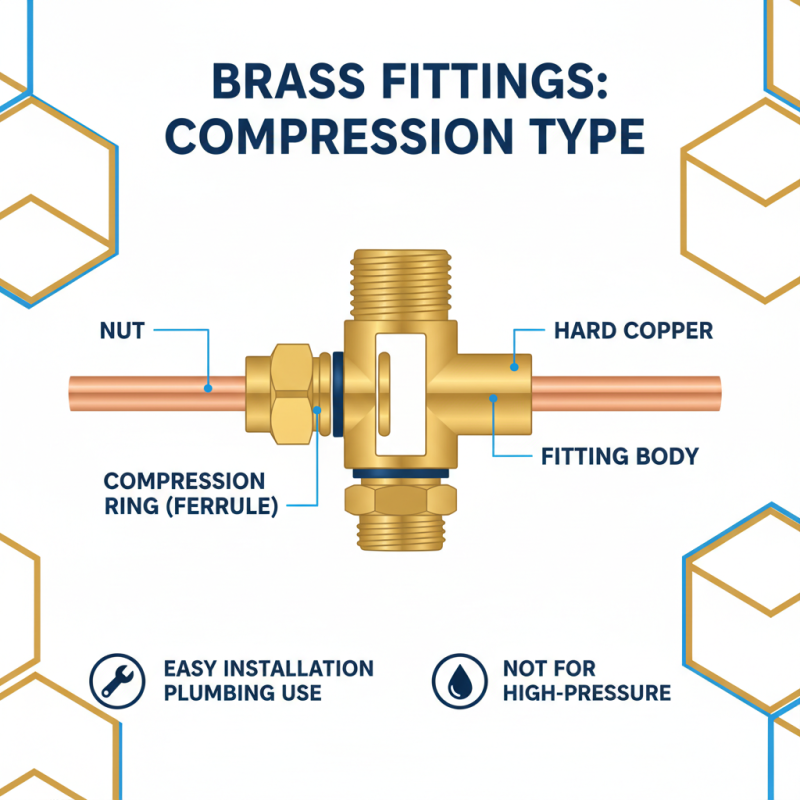

When selecting brass fittings for a project, understanding the various types is crucial. Compression fittings are popular for their ease of installation. They work well with hard and soft copper tubing. You’ll often find them in plumbing applications. Their reliability makes them a go-to option. However, they may not be best for high-pressure situations.

Another type is the threaded fittings. These are used when a secure connection is required. They can handle both gas and liquid applications. It's essential to ensure that the threads match correctly. Misalignment can lead to leaks or failure. In contrast, solder fittings offer a strong bond. They're ideal for permanent installations, often used in HVAC systems. But, they require skills in soldering, which might be a barrier for some.

Flared fittings are also noteworthy. Commonly seen in refrigerant lines, they provide a tight seal. However, creating the flared edge can sometimes be tricky. It requires precise tools and techniques. It’s easy to make a mistake that could compromise integrity. Consider all these factors before making a choice. The right fitting can simplify your work and enhance efficiency.

How to Evaluate the Quality of Brass Fittings

Evaluating the quality of brass fittings requires careful examination of several key factors. The alloy composition is crucial. High-quality brass typically consists of around 60-70% copper and 30-40% zinc. This balance offers both durability and resistance to corrosion. Low-grade fittings may contain higher levels of lead or other unwanted metals, which can compromise safety and performance.

Visual inspection plays a vital role, too. Look for signs of defects, such as uneven surfaces or discoloration. Quality brass fittings generally have a consistent finish and are free from cracks. Testing for weight can also provide insights; heavier fittings often indicate a superior material density. According to industry reports, nearly 20% of brass fittings fail within the first five years due to poor manufacturing standards.

Performance under extreme conditions is another critical aspect. Quality fittings should withstand high pressure and temperature fluctuations. In one study, over 15% of fittings showed leakage under high-pressure tests, underscoring the importance of selecting the right products for your system. While it may be tempting to choose cheaper options, the long-term costs of replacements and repairs can far exceed initial savings. Consider these factors carefully for optimal project outcomes.

Installation Tips for Brass Fittings for Optimal Performance

When installing brass fittings, attention to detail can make a significant difference. Ensure you have the right tools handy. Tightening fittings too much can cause damage. Optimal torque is key. Use a torque wrench if possible. This helps in achieving the correct tightness without risking fatigue in the fittings.

Another crucial aspect is the use of thread sealant. This can prevent leaks and enhance performance. Apply it evenly on the threads of the fitting. Be cautious not to overapply, as excess can lead to blockage in pipe systems. During assembly, take care to align the fittings properly. Misalignment may lead to stress points that can fail over time.

Testing the system after installation is crucial. Check for leaks and listen for unusual sounds. It’s a good practice to inspect your work periodically. Sometimes, issues arise after a few days. Early detection can prevent bigger problems later. Always be open to revisiting your installation process. Reflect on what went well and what could improve next time.

Related Posts

-

The Ultimate Guide to Choosing the Right Brass Fittings for Your Plumbing Needs

-

How to Choose the Right Brass Fittings for Optimal Plumbing Efficiency

-

How to Choose the Right Brass Fittings for Your Project?

-

10 Best Brass Fittings for Your Plumbing Needs?

-

2025 Top Brass Fittings: Essential Types and Buying Guide

-

Essential Checklist for Choosing the Right Brass Elbow for Your Project